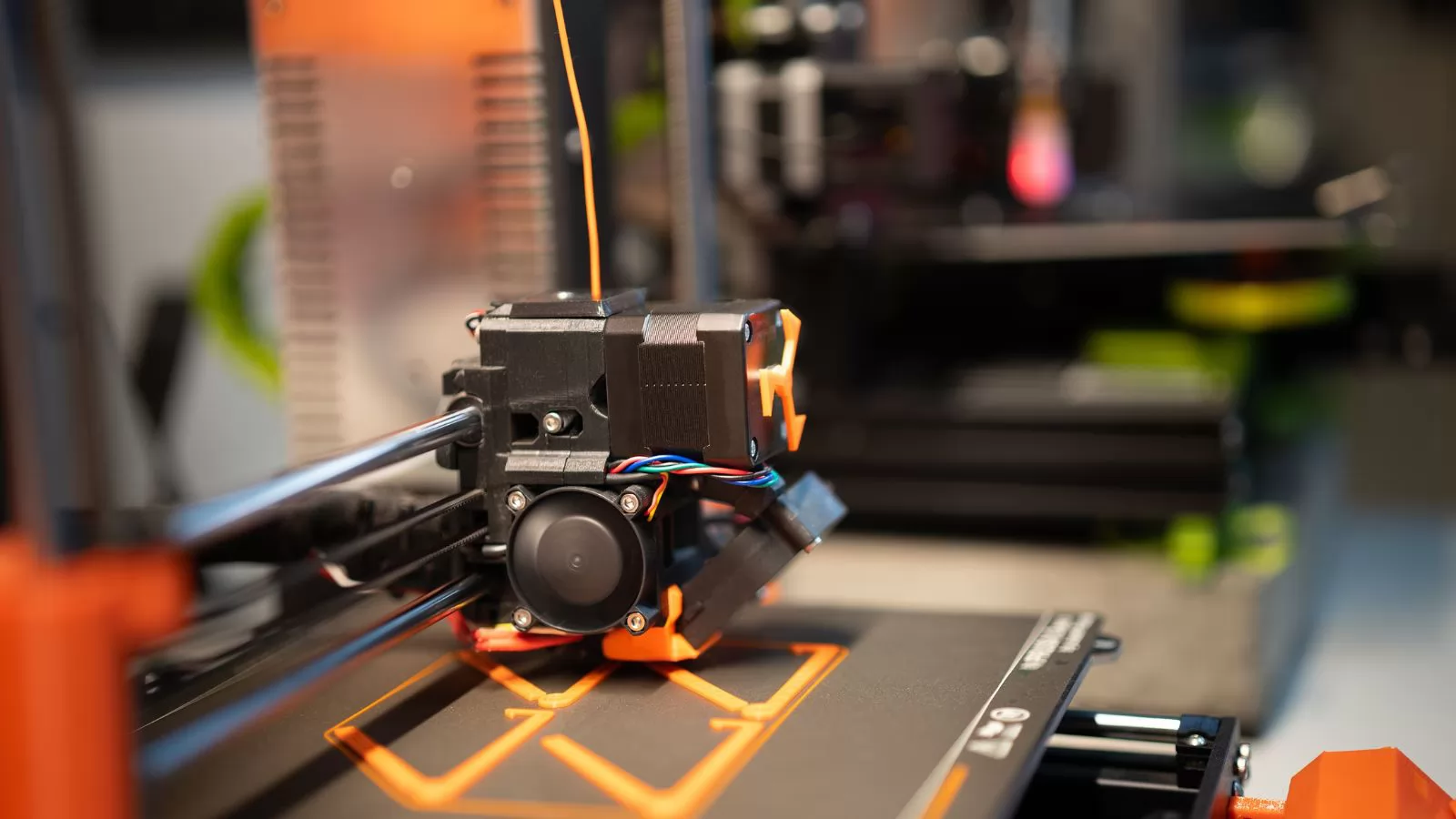

In the dynamic realm of additive manufacturing, sustainability is reshaping the industry. Post-Consumer Recycled (PCR) materials, enhanced with specialized additives, are at the forefront of this transformation. By repurposing plastic waste from everyday products like bottles, packaging, and electronics, PCR additives enable eco-friendly 3D printing without compromising quality. This in-depth guide explores the benefits, challenges, and top materials for using PCR additives in 3D printing, providing actionable insights for hobbyists, manufacturers, and sustainability enthusiasts searching for terms like "PCR 3D printing advantages" or "best recycled materials for 3D printing."

Post-Consumer Recycled (PCR) materials are derived from plastics and elastomers used by consumers and then recycled. In 3D printing, these materials are blended with additives—such as stabilizers, impact modifiers, or fillers—to optimize their performance for filament extrusion or pellet-based printing systems. Unlike virgin plastics, PCR reduces reliance on new raw materials, promoting a circular economy. Additives address common issues like inconsistent melt flow, brittleness, or thermal instability, ensuring the recycled material meets the demands of modern 3D printers.

For example, stabilizers can enhance thermal resistance, while impact modifiers improve durability. According to recent studies, PCR-based 3D printing materials can reduce carbon emissions by 70-80% compared to virgin plastics, making them a cornerstone of sustainable manufacturing.

Using PCR additives in 3D printing offers a compelling mix of environmental, economic, and technical benefits. Below are the key advantages:

These advantages position PCR additives as a top choice for those searching for "sustainable 3D printing solutions" or "eco-friendly 3D printing materials."

While PCR additives offer significant benefits, they come with challenges that users must consider. Here are the primary limitations:

Despite these challenges, advancements in recycling and additive technologies are improving PCR reliability, addressing concerns for those researching "PCR 3D printing limitations."

Choosing the right PCR material depends on your project’s requirements, such as strength, flexibility, or aesthetics. Below is a detailed table of top PCR materials, their properties, and ideal applications:

| Material | Type | Key Properties | Best For | Carbon Emissions (ton CO2e/ton) |

|---|---|---|---|---|

| PC-103AR | PCR Polycarbonate |

MFR (Melt Flow Rate) 12~18 g/10min

Notched IZOD Impact ≥700 J/m

|

Transparent prototypes, optical parts | 0.7216 |

| rABS-NE115CG | PCR ABS |

MFR (Melt Flow Rate) 20~30 g/10min

Notched IZOD Impact ≥15 KJ/㎡

|

Durable consumer goods, enclosures | 0.7153 |

| rPA6-S22N | PCR Polyamide 6 |

Notched IZOD Impact 5 KJ/㎡

Tensile Strength 55 MPa

|

Engineering parts, gears | 0.7208 |

These materials, available from suppliers like Topcentral, are GRS-certified and optimized for both filament and pellet-based 3D printing. Additional popular PCR options include:

For best results, opt for materials with high PCR content (e.g., 100% recycled) and test small batches to ensure compatibility with your printer.

PCR additives are transforming industries by enabling sustainable manufacturing. Key applications include:

3D printing with PCR additives is a game-changer for sustainable manufacturing, offering a balance of environmental responsibility and practical performance. Benefits like reduced carbon emissions, cost savings, and enhanced material properties make PCR an attractive choice, while limitations like quality variability require careful material selection and printer adjustments. Top materials like PCR PLA, PET, ABS, and specialized blends from Topcentral cater to diverse needs, from prototyping to industrial applications.

For those exploring "eco-friendly 3D printing materials" or "PCR additive manufacturing," start with certified suppliers and experiment with small batches to optimize results. As recycling technologies advance, PCR will play a pivotal role in the future of additive manufacturing. Visit Topcentral for tailored solutions and stay ahead in the circular economy.

This article reflects industry insights as of September 24, 2025, and is designed to provide expert, trustworthy guidance for your 3D printing projects.

Discover this amazing content and share it with your network!

Discover the successful Ningbo session of the 9th National Coastal Cleanup Campaign. Families, youth, and eco-teams united to protect the ocean, advocate recycling, and promote sustainable coastal action.

Explore recycled AS pellets: transparent, BPA-free, high-performance sustainable plastic for consumer goods, packaging, electronics, and automotive applications.

Topcentral® joined China’s national delegation at K 2025 Düsseldorf to promote sustainable polymer innovation and global circular economy collaboration.