At the 2025 Seminar on High-Quality Development of the Polycarbonate Industry held recently in Wuxi, Jiangsu, over 100 industry leaders proposed solutions to the intense competition—commonly referred to as "neijuan" (internal over-competition)—plaguing the PC sector: move beyond price wars and toward value-driven competition. “The future of the PC industry does not lie in fighting in the red ocean of ‘neijuan,’ but in exploring the blue ocean of innovation,” said He Shengbao,Chairman of the China Synthetic Resin Association. The structural imbalance—overcapacity in low-end products and insufficient supply of high-end ones—is becoming increasingly evident. Self-sufficiency in general-grade PC has exceeded 100%, while domestic production of high-end grades such as medical- and optical-grade materials remains below 30%.

_1755761974_WNo_1014d576.webp)

Polycarbonate (PC), as a high-performance engineering plastic, is facing unprecedented market challenges. According to the China Synthetic Resin Association, since 2021, China's PC production capacity has exceeded apparent consumption. Rapid capacity expansion is the main driver: over the past five years, China’s PC capacity has grown from 1.66 million tons in 2019 to 3.81 million tons in 2025, accounting for 48% of global capacity, with a compound annual growth rate of 15.5%.

Despite this, emerging sectors such as new energy vehicles and advanced healthcare are creating new growth opportunities. Leveraging PC’s excellent performance and declining prices, these industries are expanding their use of polycarbonate.

"De-homogenization" has become a key theme for high-quality development in the PC industry. Experts suggest three strategic pathways for breakthrough:

Prior to this, Topcentral® partnered with Wahaha Group to recycle post-consumer used water bottles, offering a concrete example of green transformation in the PC industry.

As a leading enterprise in China’s bottled water market, Wahaha generates millions of end-of-life PC water containers annually. Topcentral®’s end-to-end recycling supply chain and digital service solution collects these discarded bottles, transforms them through advanced recycling technologies into high-performance PFZ® PCR PC® materials, and collaborates with partners to apply them in innovative fields—driving product innovation and market breakthroughs.

Through precise sorting, shredding, deep cleaning, pelletizing, and modification processes, Topcentral®’s R&D team has developed 100% post-consumer recycled, zero-carbon green polycarbonate—FreeCBO2® PCR PC®. The material matches international advanced standards in both performance and sustainability, providing strong support for further technological and application innovations.

_1755761988_WNo_1080d720.webp)

By collaborating with industrial partners, Topcentral® has successfully applied recycled PCR PC® in electronics components, automotive parts, sports equipment, business travel products, and food packaging—creating a sustainable value chain that transforms waste into diversified technological and commercial innovations. This model not only turns waste into valuable resources and reduces pollution but also significantly lowers carbon emissions and enables high-value applications:

Looking ahead to the next five years, domestic PC supply growth is expected to slow to around 5%, while apparent consumption may grow at approximately 4.5%, signaling a new phase of supply-demand rebalancing. Topcentral®’s diverse innovations and partnerships will further accelerate the industry’s journey toward a sustainable, circular, and carbon-neutral future. Topcentral®’s bold exploration and continuous practice prove: waste is not an endpoint, but the starting point of a new value chain. When leading enterprises embrace the circular economy and carbon-neutral ecosystems, China’s manufacturing sector is rapidly advancing toward a new paradigm of infinite recycling and sustainable development.

Discover this amazing content and share it with your network!

Topcentral® presents Oceancycle innovations, showcasing marine waste recycling, high-value regeneration technologies, and sustainable circular solutions demonstrated at the Tokyo High-Performance Plastics & Composites Exhibition.

Topcentral® shares its ecological innovation practices at the Tokyo High-Performance Plastics & Composites Exhibition, showcasing PCR technologies, circular solutions, blockchain traceability, and digital product passport applications for global sustainability and carbon neutrality.

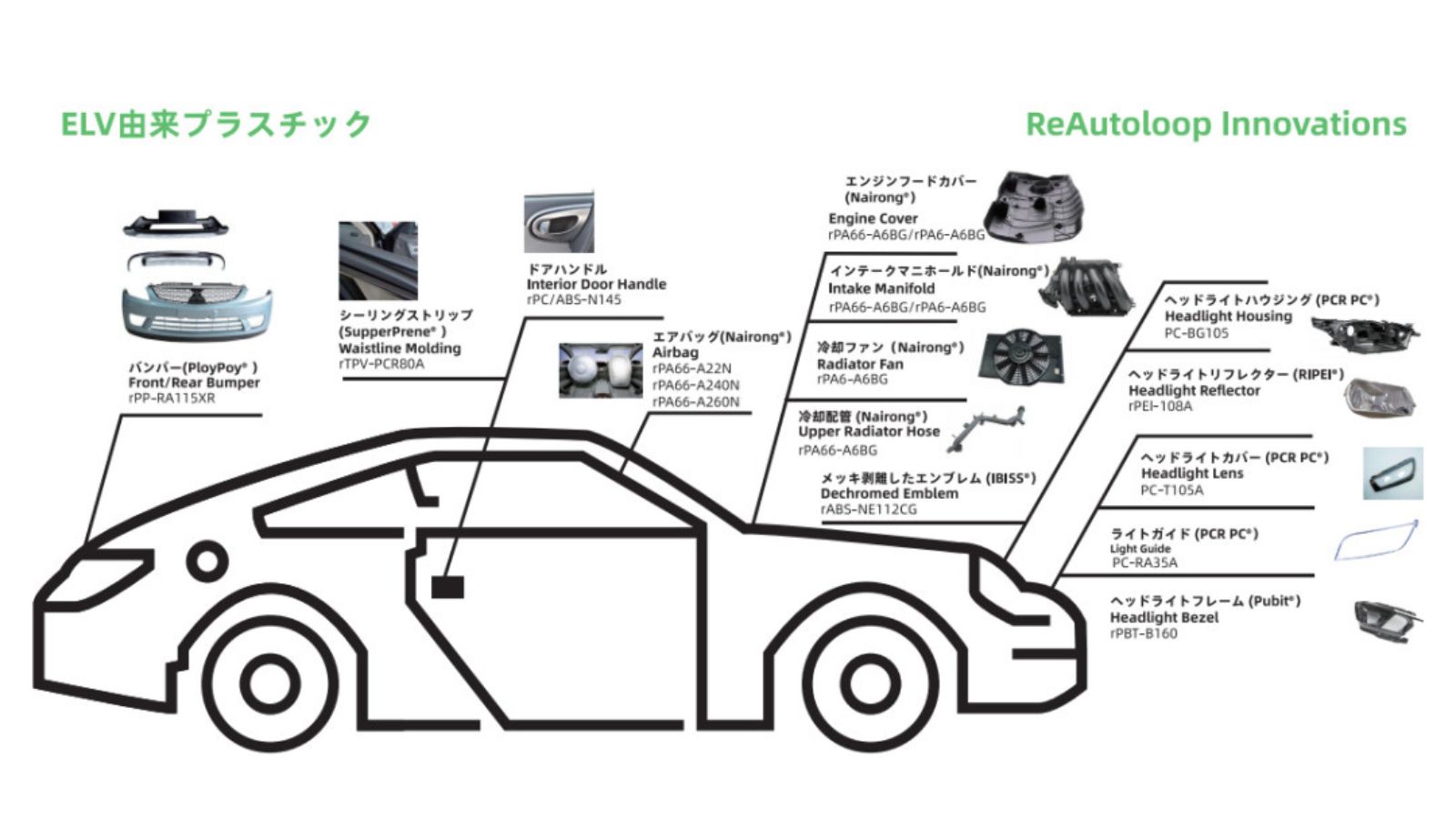

Topcentral® (坚锋®) launches the ReAutoLoop Innovations project to advance global automotive recycling and plastic circularity through closed-loop systems, sustainable innovation, and international collaboration.