Post-Consumer Recycled (PCR) material refers to plastics that have completed their life cycle as consumer items and have been diverted from landfills or incineration to be reclaimed. Unlike virgin resins derived directly from fossil fuels, PCR plastics are generated from waste streams such as discarded packaging, electronic devices, and automotive components. In the context of industrial manufacturing, transforming this waste into high-quality raw material requires rigorous sorting, cleaning, and compounding processes to ensure the feedstock meets engineering specifications.

For B2B manufacturers and molders, adopting PCR is not merely an environmental gesture but a strategic adaptation to the circular economy. It involves reintegrating materials into the supply chain that have genuinely served an end-use purpose. This distinction is critical for regulatory compliance, such as meeting EPEAT or EU Ecodesign standards, which specifically mandate "post-consumer" content rather than general recycled content.

Common types of engineering-grade PCR plastics utilized in technical applications include:

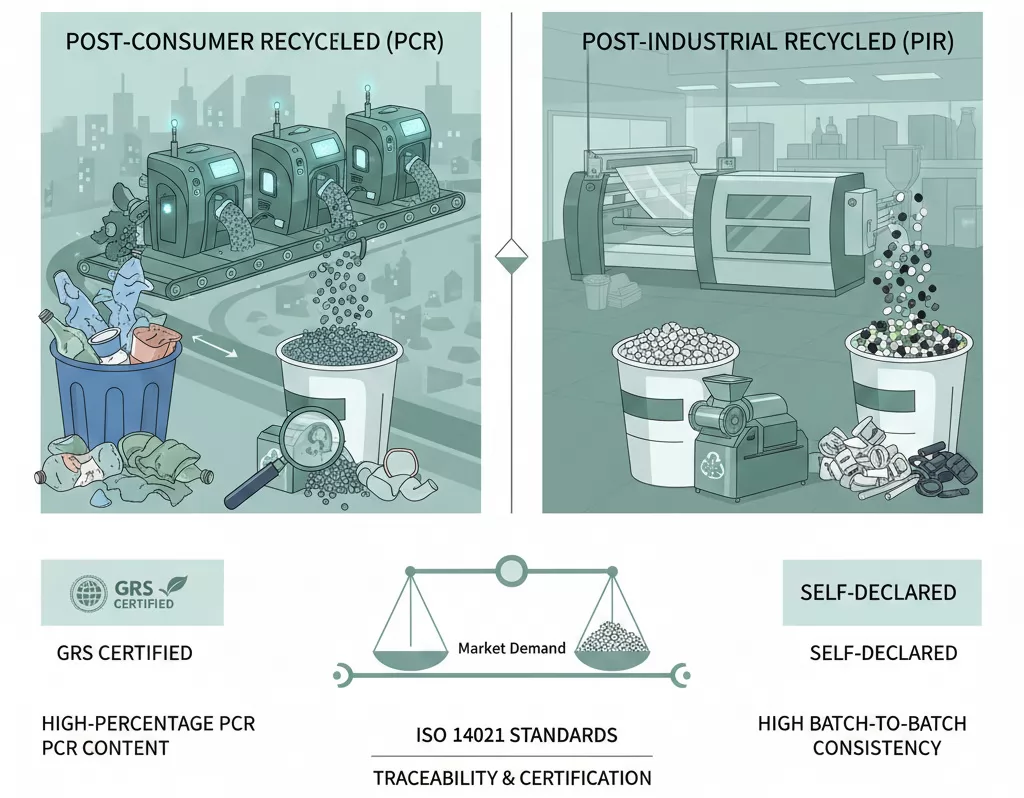

In the plastics industry, distinguishing between Post-Consumer Recycled (PCR) and Post-Industrial Recycled (PIR) is fundamental for accurate material specification and sustainability reporting. While both divert waste from landfills, their origins, processing requirements, and environmental impacts differ significantly under international standards like ISO 14021.

Post-Industrial Recycled (PIR), sometimes referred to as pre-consumer recycled, originates from waste generated during the manufacturing process itself. This includes sprues, runners, edge trims, and off-spec parts that never left the factory floor. Because the material history is known and contamination is minimal, PIR is relatively easy to reprocess into high-quality pellets. However, reusing PIR is often considered standard efficiency practice rather than a solution to the global plastic waste crisis.

Post-Consumer Recycled (PCR) comes from products that have been used by a consumer and discarded. This stream is inherently more complex due to potential contamination (inks, adhesives, mixed materials) and degradation from UV exposure or weathering. Transforming PCR into an engineering-grade resin requires advanced sorting, washing, and compounding technologies to restore its physical properties. Despite these challenges, PCR is valued higher in corporate sustainability goals because it directly addresses the problem of end-of-life plastic pollution.

When selecting materials for B2B applications, engineers must weigh the following differences:

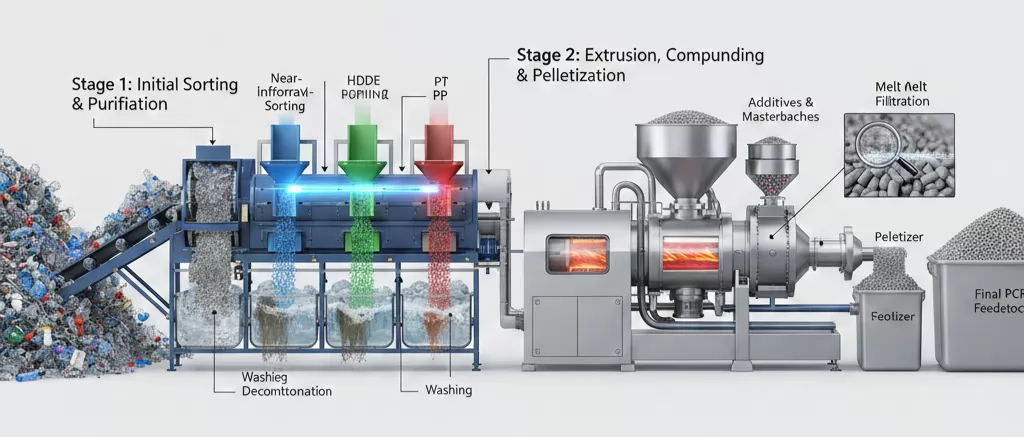

The transformation of heterogeneous post-consumer waste into a reliable, consistent manufacturing feedstock is a complex industrial process. It involves multiple stages of purification and material engineering to compensate for the degradation and contamination acquired during the material’s first lifecycle. This processing is what differentiates high-grade PCR from simple recycled scrap.

The first critical step involves separating the mixed waste stream into specific polymer types. Modern recycling facilities rely heavily on automation for precision:

Once the material is dried and converted into clean flakes or shreds, it enters the compounding stage. This is the critical engineering phase where material properties are restored and optimized for molding or extrusion applications:

The clean PCR flakes are fed into a twin-screw extruder where they are melted, mixed, and homogenized. Key technical operations performed during compounding include:

The resulting molten material is then cooled and cut into uniform pellets (regranulation), which is the final PCR resin feedstock ready for injection molding or other industrial processes.

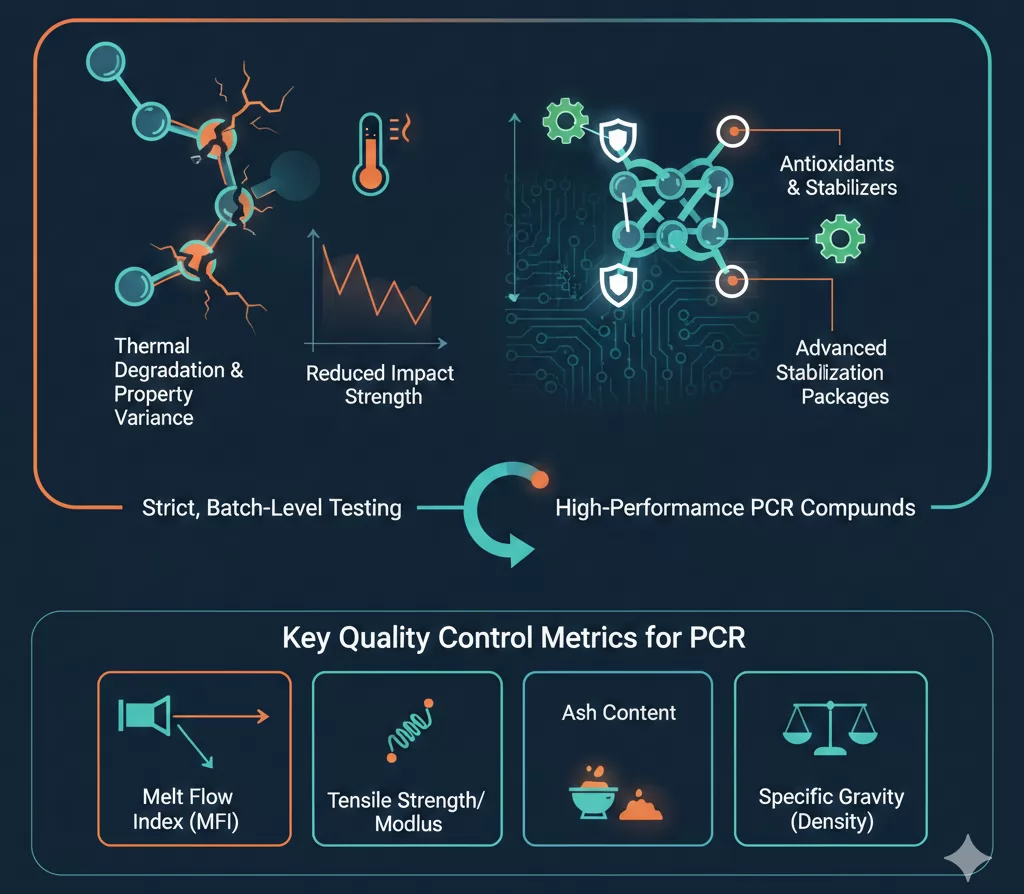

For manufacturers, the successful integration of PCR materials hinges on their ability to maintain consistent mechanical, thermal, and rheological properties comparable to virgin resins. Since PCR has undergone prior heating and stress cycles, its molecular structure is often degraded, making specialized quality control and modification essential.

Polymers experience chain scission (molecular breakdown) during processing, which can lead to reduced mechanical performance in the resulting PCR resin. This is particularly noticeable in impact strength (e.g., Izod or Charpy tests) and elongation at break. To counteract this inherent variance, compounders must utilize advanced stabilization packages:

Engineers must specify PCR based on tested metrics, not just percentage content. The most critical parameters for ensuring reliable production include:

| Metric | Purpose in PCR Assessment |

|---|---|

| Melt Flow Index (MFI) | Determines flow characteristics in injection molding. Inconsistent MFI leads to filling defects and dimensional instability. |

| Tensile Strength/Modulus | Measures the material's stiffness and resistance to deformation. Essential for load-bearing components. |

| Ash Content | Indicates the level of inorganic contaminants (e.g., mineral fillers or non-melting foreign debris). High ash content damages tooling and weakens the final part. |

| Specific Gravity (Density) | Used to verify material consistency and calculate component weight for cost analysis. |

Only through strict, batch-level testing and quality assurance protocols can manufacturers mitigate the risk of property degradation and successfully substitute virgin resin with high-performance engineered PCR compounds.

The industrial adoption of Post-Consumer Recycled (PCR) materials is rapidly expanding beyond simple consumer goods. Driven by aggressive corporate sustainability mandates, regulatory frameworks (such as the EU's plastic directives), and technical advancements in compounding, PCR is now a viable material for demanding, high-performance applications.

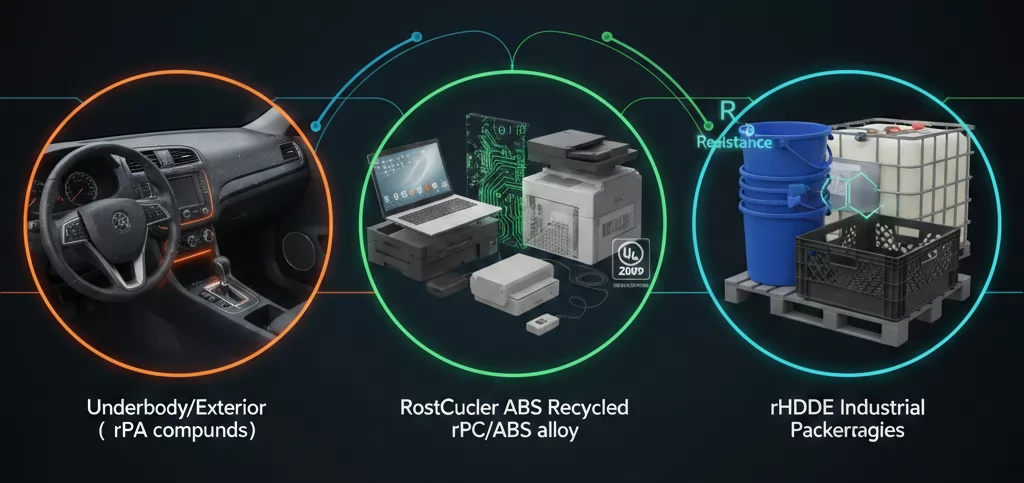

The E&E sector is a major driver for high-grade PCR, particularly for engineering plastics. The challenge here is meeting strict requirements for flame retardancy, impact resistance, and aesthetic finish. PCR derived from WEEE (Waste Electrical and Electronic Equipment) is commonly used to close the material loop:

In the automotive industry, PCR adoption is focused on maximizing sustainability while maintaining crash performance and thermal stability. OEMs are increasingly specifying materials for both interior and non-critical exterior components:

The highest volume application for PCR remains in packaging, but industrial use focuses on durable, multi-use items rather than single-use consumer items. Consistency and chemical resistance are the primary requirements.

This includes injection-molded products such as industrial buckets, storage containers, pallets, and intermediate bulk container (IBC) accessories, primarily utilizing rHDPE and rPP streams due to their excellent resistance to chemicals and robust physical properties.

The primary strategic driver for adopting Post-Consumer Recycled (PCR) materials is the substantial reduction in the product’s overall environmental footprint. Compared to the complex processes required for extracting and refining petrochemicals to produce virgin resin, the mechanical recycling process of PCR is significantly less resource-intensive. This difference is quantifiable through a Life Cycle Assessment (LCA).

The utilization of PCR feedstock yields critical savings across several key environmental metrics:

For manufacturers focused on Environmental, Social, and Governance (ESG) reporting, incorporating verifiable PCR content is a direct, measurable method of supporting circular economy goals. It shifts the corporate paradigm from a linear "take-make-dispose" model to one where material value is retained and recycled inputs become a reliable feature of the supply chain.

The successful adoption of Post-Consumer Recycled (PCR) materials requires manufacturers to anticipate and proactively manage several key technical challenges related to material heterogeneity and previous thermal exposure. These challenges primarily impact processing efficiency and the final product's aesthetic quality.

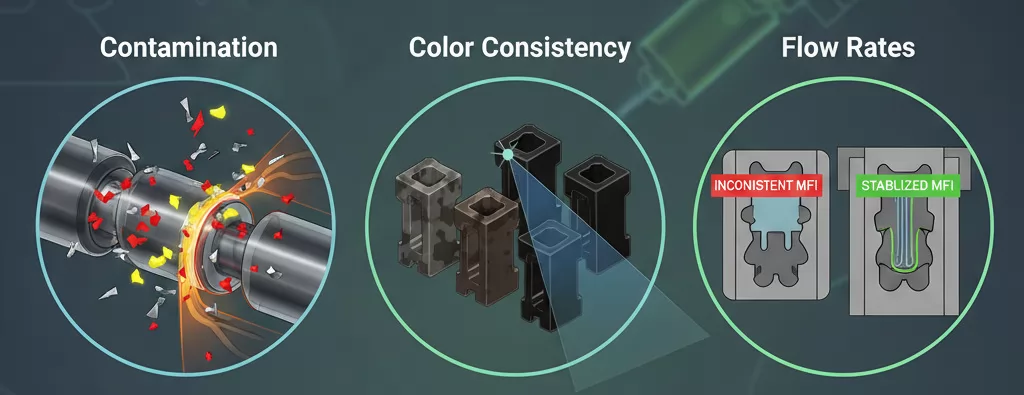

Residual contaminants pose the most significant risk to the manufacturing equipment. Even after advanced cleaning, PCR can retain trace amounts of non-polymer material (ash), which include glass, metal filings, or mineral particles. These act as abrasive elements during molding and extrusion, leading to:

Solution: High-quality PCR suppliers use sub-100 micron melt filtration. Processors should prioritize suppliers who provide materials with a verified low ash content percentage, coupled with specialized filtration equipment on their own processing line.

The mixed nature of post-consumer waste results in a base resin color that is often inconsistent, dark, or mottled. Achieving vibrant, light, or precise corporate colors using high-percentage PCR is difficult and costly.

Solution: To ensure aesthetic reliability, manufacturers typically opt for two strategies:

The rheology (flow characteristics) of PCR resin can vary more significantly than virgin resin due to the different thermal histories of the source materials. Inconsistent Melt Flow Index (MFI) can lead to major processing issues, such as short shots, inconsistent part weight, and increased cycle times.

Solution: Compounders stabilize the MFI through precise molecular weighting and the inclusion of flow stabilizers. On the processing side, technicians must implement dynamic control strategies, potentially requiring minor adjustments to barrel temperatures and injection pressures based on the Certificate of Analysis (CoA) provided for each new PCR batch, rather than relying solely on fixed parameters.

For manufacturers, substantiating the use of Post-Consumer Recycled (PCR) content requires more than a simple declaration. Third-party verification standards and regulatory compliance are essential tools for ensuring traceability, preventing greenwashing, and accessing markets that mandate sustainable sourcing. Procurement teams must demand certificates that validate the feedstock’s origin.

The Global Recycled Standard (GRS) and the Recycled Claim Standard (RCS) are widely adopted standards that verify the percentage of recycled content in a material. Critically, these standards mandate a Chain of Custody (CoC) protocol, ensuring that:

The UL 2809 Environmental Claim Validation Procedure is a standard developed by UL (Underwriters Laboratories) specifically to authenticate the recycled content claims of a material. This certification is particularly valuable in the electronics, IT, and appliance sectors. It provides assurance that:

The material designated as "post-consumer" truly originated from end-of-life products, adhering to strict definitions that separate it from the cleaner, less environmentally impactful Post-Industrial Recycled (PIR) streams.

Compliance extends beyond voluntary certification. Manufacturers must also adhere to official terminology and regulatory mandates:

Successfully integrating Post-Consumer Recycled (PCR) materials requires a strategic shift in procurement, moving away from simple commodity purchasing toward technical partnership. Due to the inherent variability of the waste stream, a stable PCR supply relies heavily on the compounder’s expertise in quality control and modification.

Manufacturers must establish specific technical due diligence criteria when selecting a PCR supplier:

By treating PCR as an engineered product rather than a simple substitution, manufacturers can reliably meet sustainability targets while maintaining high standards of quality and process efficiency.

Discover this amazing content and share it with your network!

A definitive technical guide to Post-Consumer Recycled (PCR) material. Learn about processing, performance analysis, certifications (GRS, UL), and strategic sourcing for B2B applications.

China's leading manufacturer of sustainable low-carbon materials, Topcentral, offers GRS and UL OBP certified PCR (Topcircle®) solutions. We address the marine plastic crisis at its source and are committed to leading a green, low-carbon future.

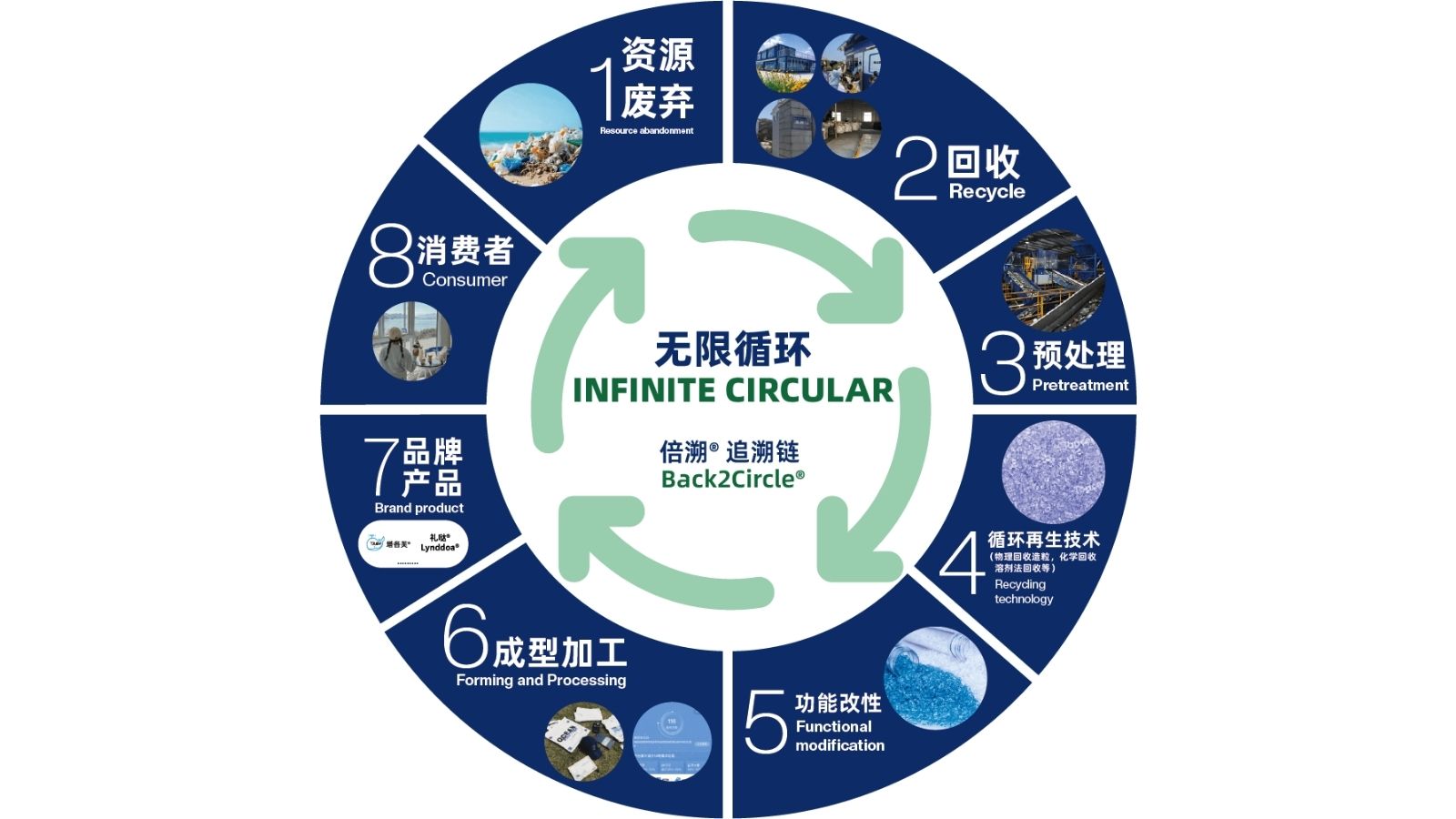

Topcentral's Back2Circle® platform uses TraceBytes® Blockchain and iDNAXx® to create immutable CarbonID™ (DPP) for PCR materials. Achieve full lifecycle transparency and compliance.