/

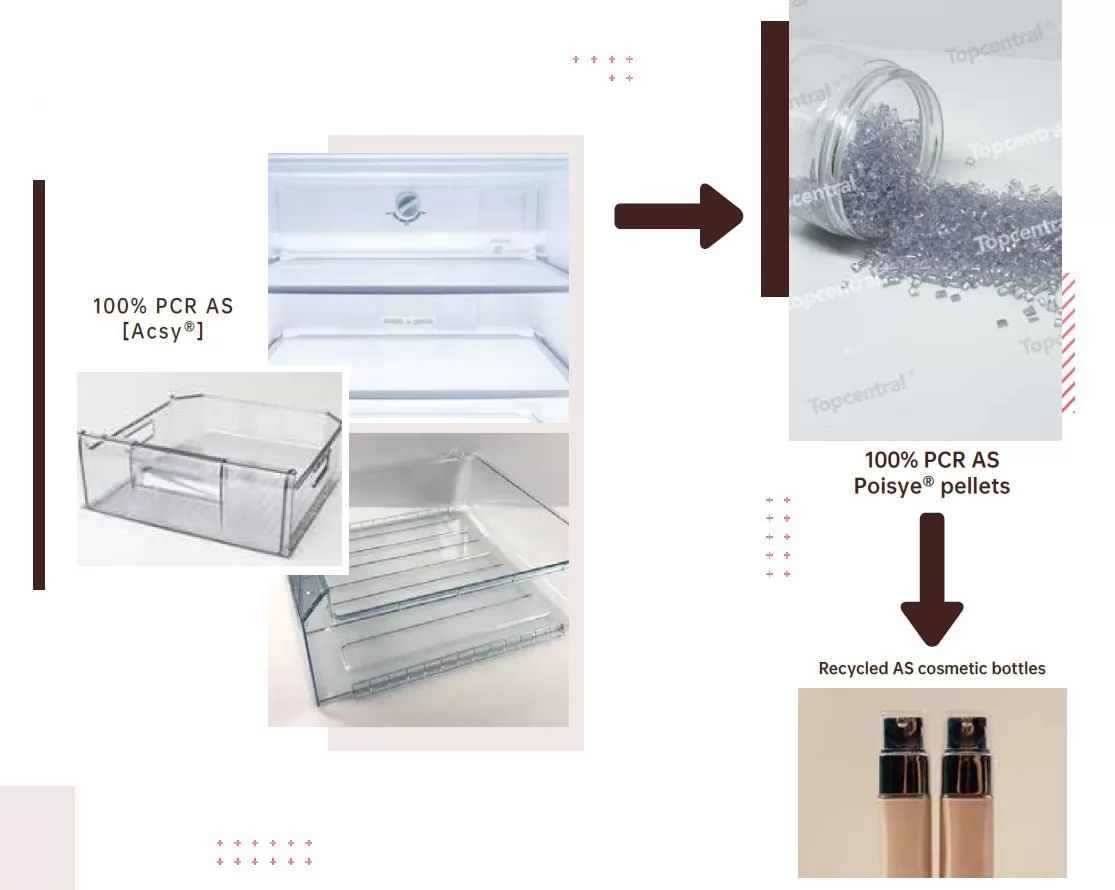

PCR Acrylonitrile-styrene copolymer(rAS)(Acsy® )

| Typical grade | Intrinsic viscosity (dI/g, 25°C) | PCR content | Water content (%) | Appearance | Carbon footprint t CO₂e/t | Certification | Application | Characteristics |

|---|---|---|---|---|---|---|---|---|

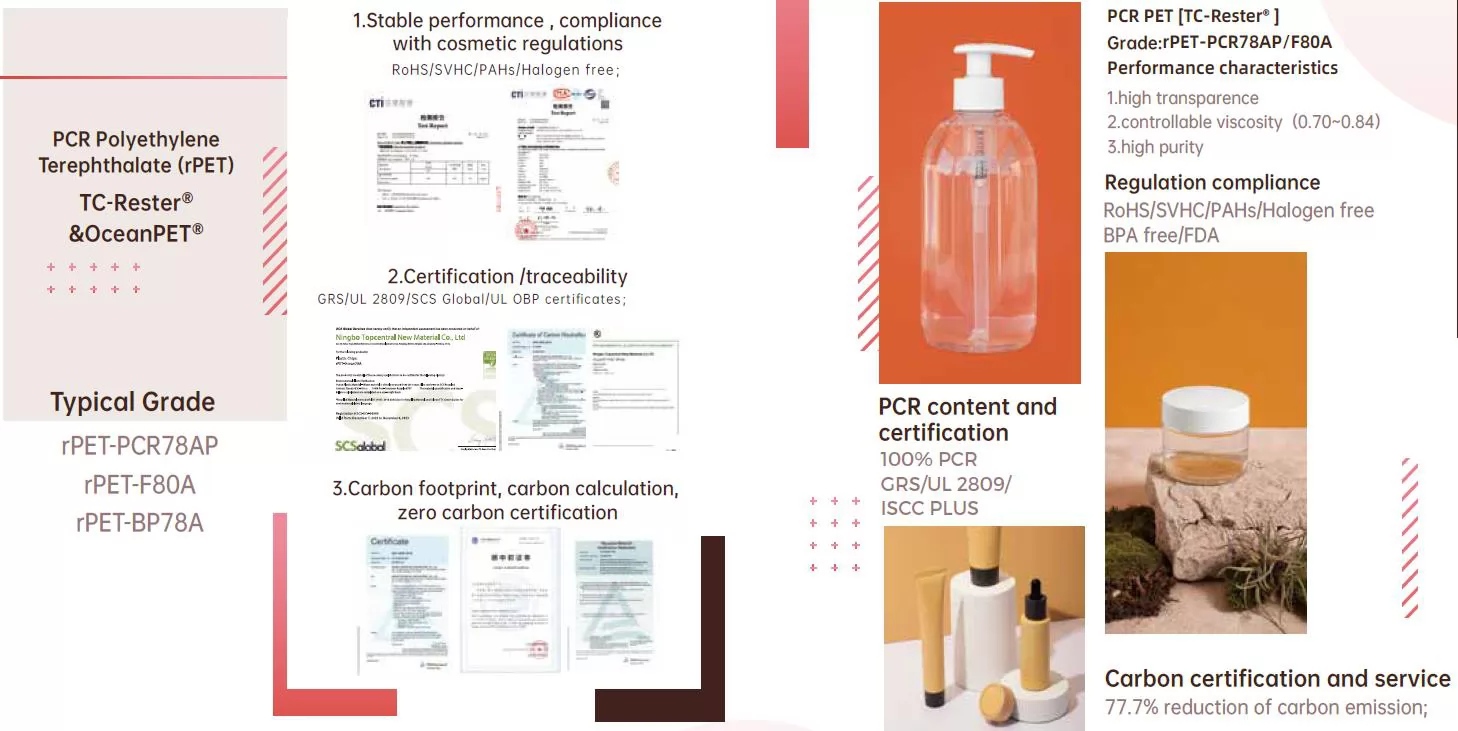

| rPET-PCR78AP | 0.65~0.80 | 100% | ≤0.4 | Transparent Milky White | 0.6939 | GRS/UL 2809/Zero-carbon/ISCC PLUS | Spinning/modification/extrusion/injection Molding | FreeCB02® |

| rPET-F80A | 0.60~0.80 | 100% | ≤0.4 | Transparent Milky White | 0.7249 | GRS/UL 2809/ISCC PLUS | Spinning/modification/extrusion/injection molding/filming | FDA Tested |

| Coastbound® | 0.60~0.80 | 100% | ≤0.4 | Transparent Milky White | 0.7213 | GRS/UL OBP/ISCC PLUS | Spinning/modification/ degradation/extrusion/injection molding | FreeCB02® |

| Typical grade | Melt index (g/10min) | Notched impact strength (KJ/m²) | PCR content | Appearance | Carbon footprint t CO2e/t | certification | Application | Characteristics |

|---|---|---|---|---|---|---|---|---|

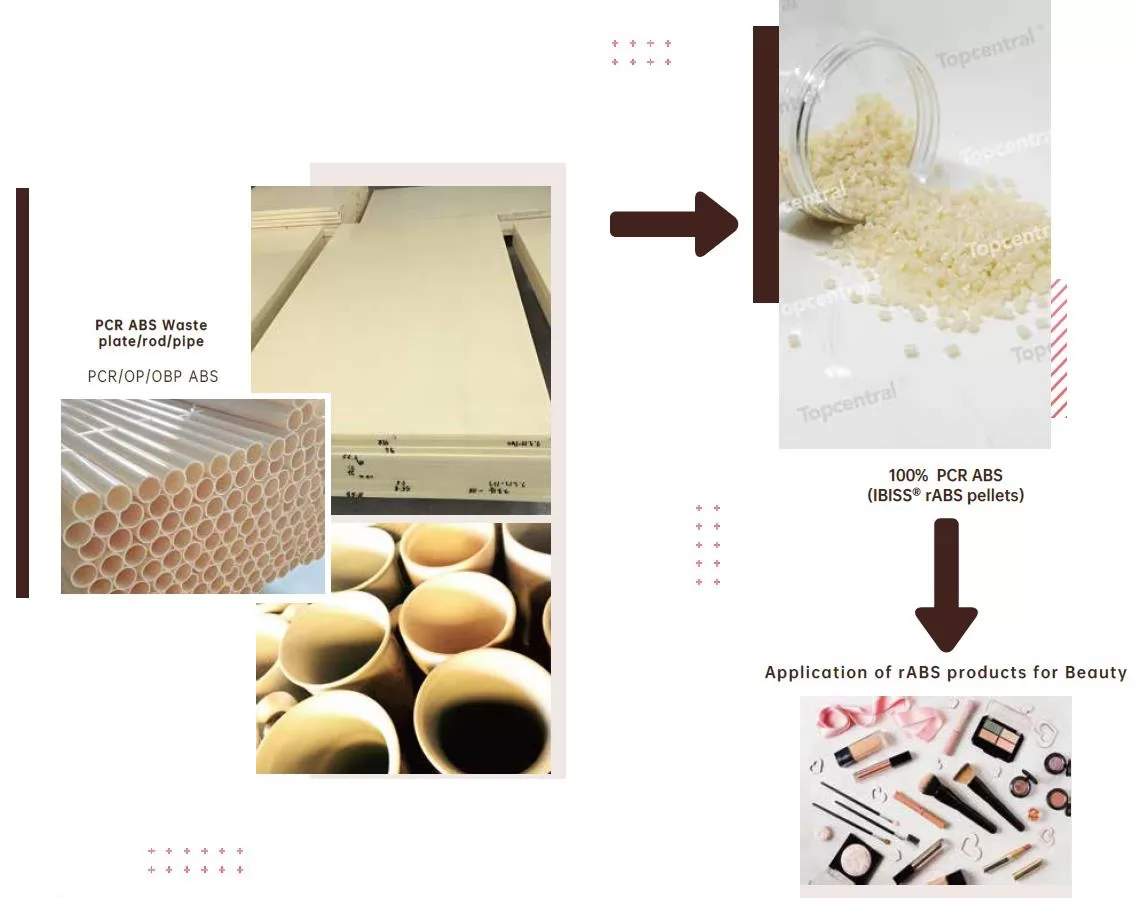

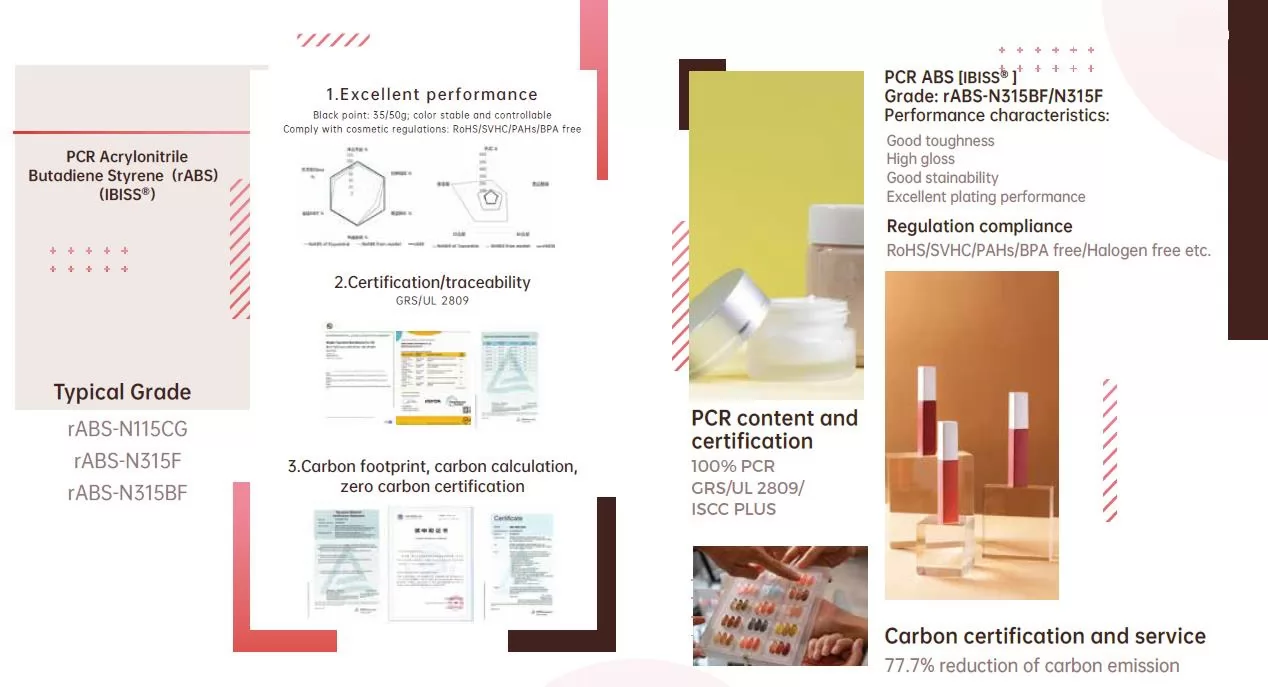

| rABS-N315F | 15-25 | ≥15 | 100% | Natural | 0.7018 | UL 2809/GRS/ISCC PLUS | modification/injection molding | FDA |

| rABS-N315BF | 30-45 | ≥15 | 100% | Natural | 0.6923 | GRS/ISCC PLUS | modification/injection molding | BPA free/FDA |

| rABS-N115CG | 20-30 | ≥15 | 100% | Natural | 0.7153 | UL 2809/GRS/ISCC PLUS | modification/injection molding | High Gloss |

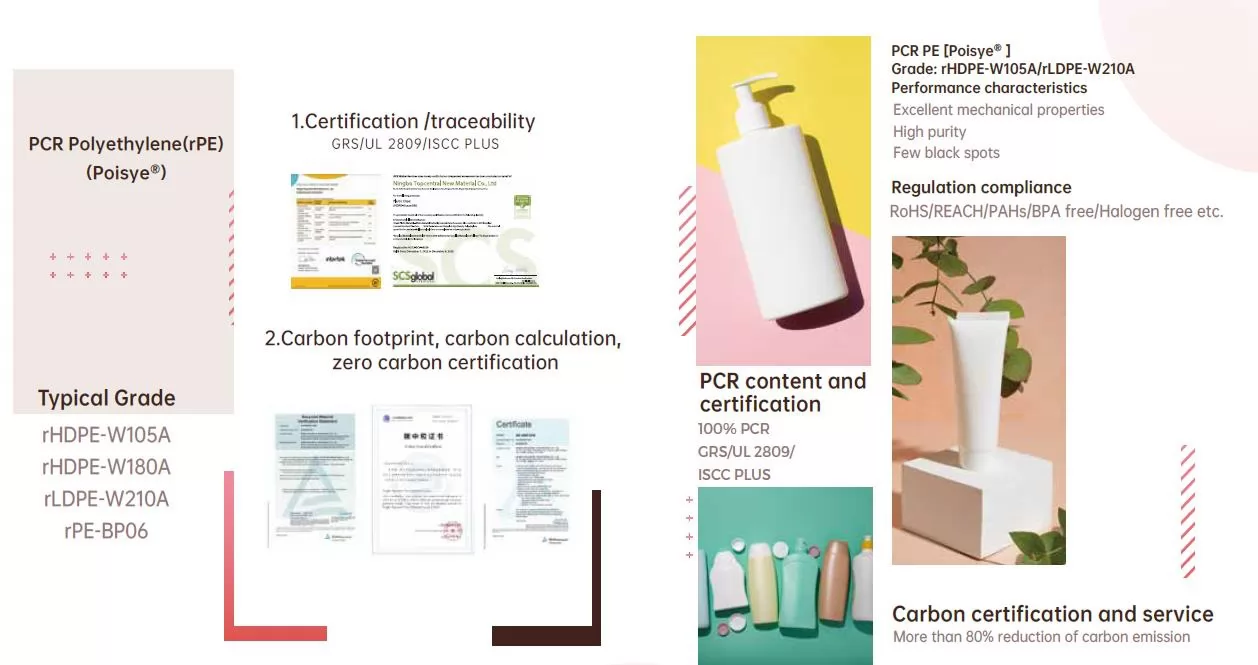

| Type | Melt index (g/10min) | Notched impact strength (KJ/m2) | PCR content | Tensile strength | Appearance | Carbon footprint t CO2e/t | Certification | Application |

|---|---|---|---|---|---|---|---|---|

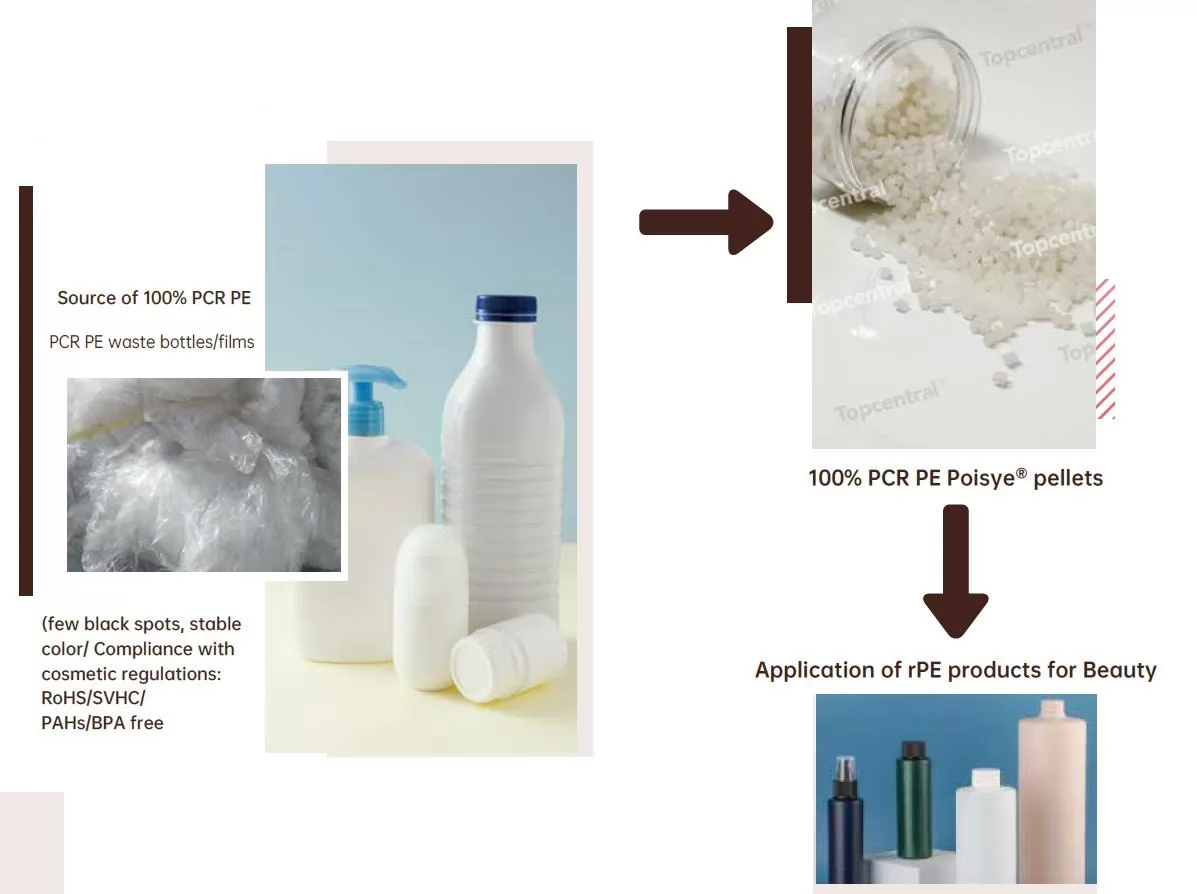

| rHDPE-W105A | 0.1~1 | ≥20 | 100% | ≥20 | Natural | 0.6216 | GRS/ISCC PLUS | Blow molding |

| rLDPE-W210A | 0.2~5 | - | 100% | ≥10 | Natural | 0.6179 | GRS/ISCC PLUS | Blow molding |

| rHDPE-W180A | 5~10 | ≥4 | 100% | ≥18 | Natural | 0.6129 | GRS/ISCC PLUS | Injection molding |

| Coastbound® | 0.1~6 | ≥3 | 100% | ≥15 | Natural or Black | 0.6125 | GRS/ISCC PLUS/UL OBP | Motivation, extrusion, injection molding daily necessities |

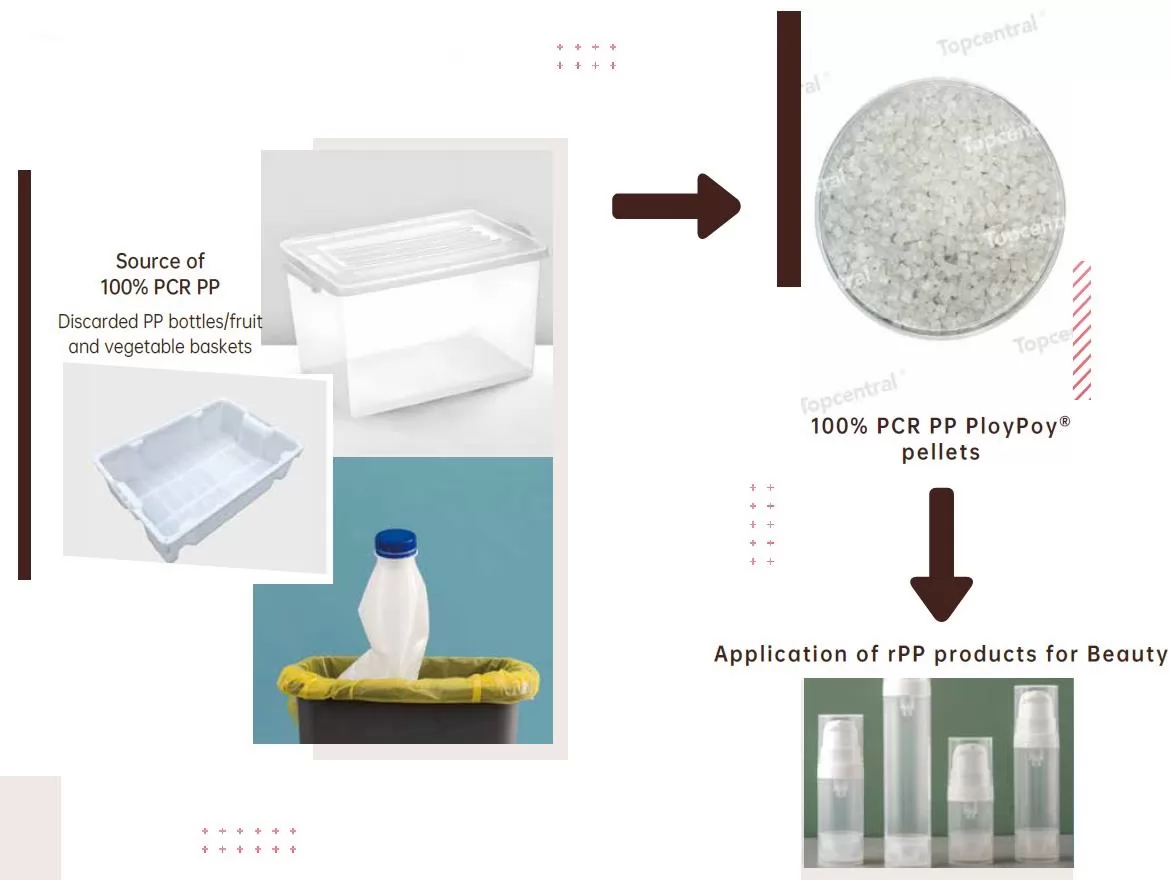

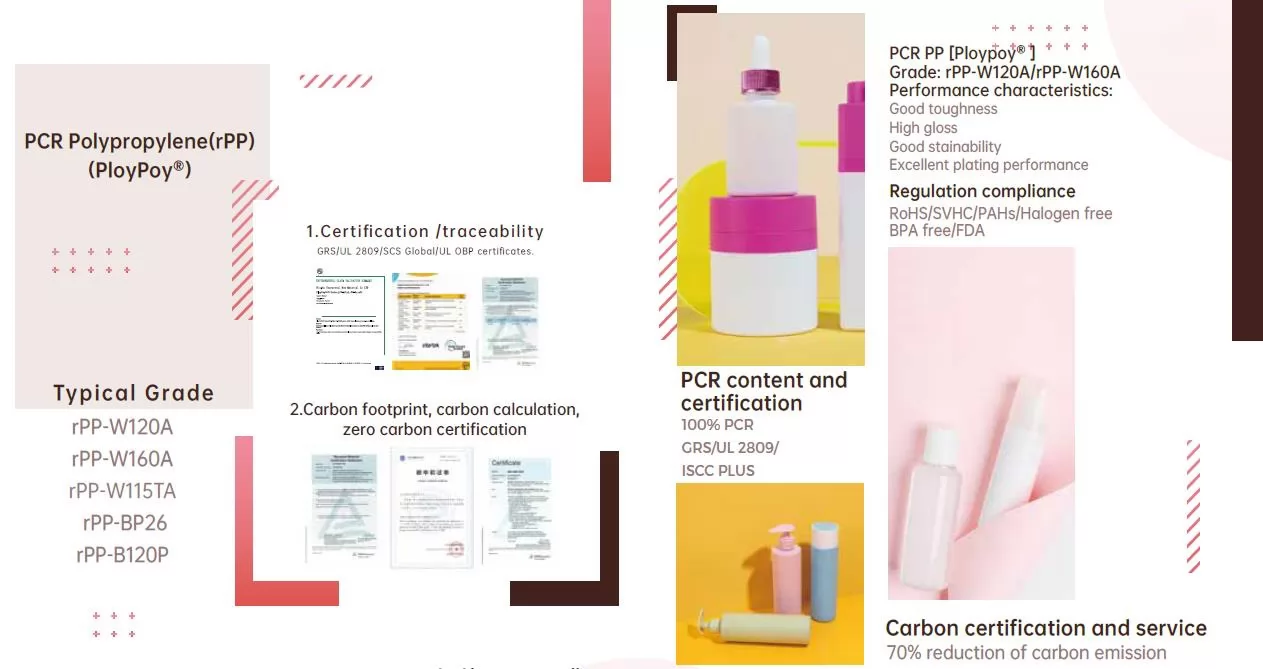

| Type | Melt index (g/10min) | PCR content | Notched impact strength (KJ/m2) | Tensile strength (MPa) | Appearance | Carbon footprint t CO2e/t | Certification | Typical Application |

|---|---|---|---|---|---|---|---|---|

| rPP-W120A | 1-4 | 100% | ≥5 | ≥20 | Natural | 0.6781 | GRS/SCC PLUS | Blow molding/extrusion/injection molding |

| rPP-W160A | 4-8 | 100% | ≥5 | ≥20 | Natural | 0.6702 | GRS/SCC PLUS | Injection molding |

| rPP-W115TA | 12-18 | 100% | ≥3 | ≥20 | Natural | 0.7523 | GRS/SCC PLUS | Injection molding |

| Coastbound® rPP-BP26 | 2-10 | 100% | ≥3 | ≥15 | Natural or Black | 0.6957 | GRS/JUL OBP/SCC PLUS | Modification, extrusion, injection molding, daily necessities |

| Coastbound® rPP-B120P | 2-10 | 100% | ≥5 | ≥18 | Natural or black | 0.7016 | GRS/JUL OBP/SCC PLUS | Modification, extrusion, injection molding, daily necessities |

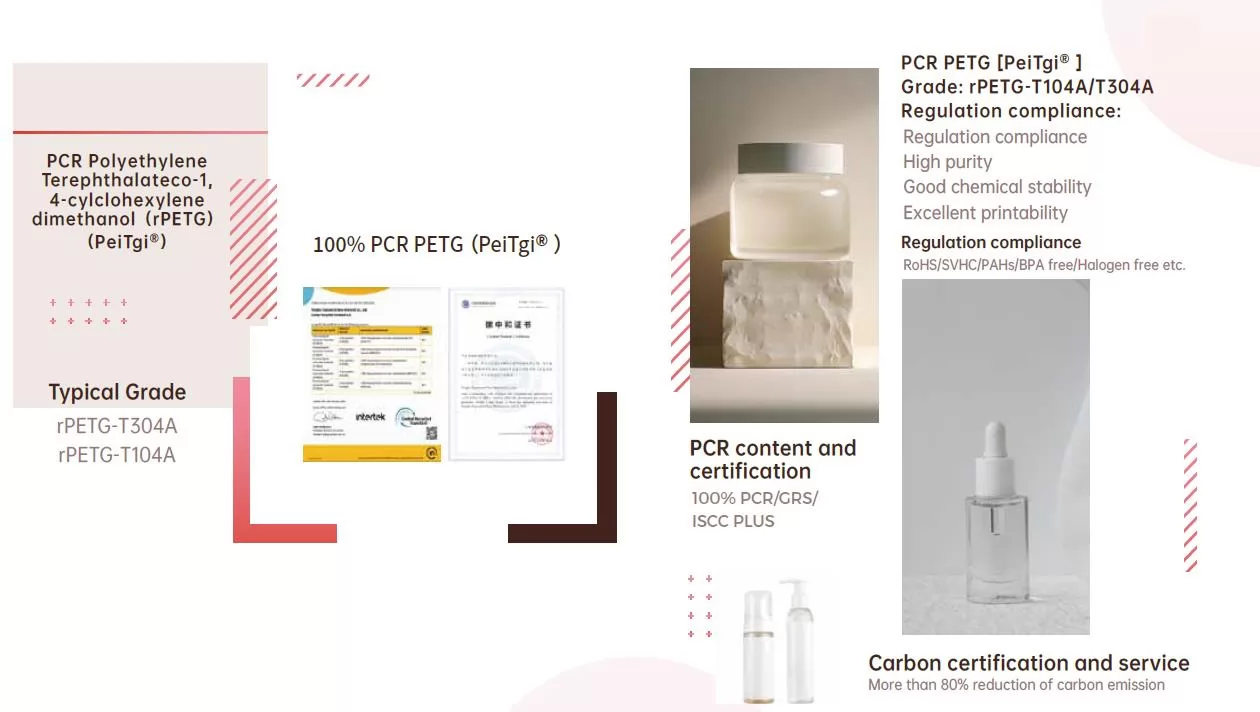

| Typical grade | Melt index (g/10min) | PCR content (%) | Tensile strength (MPa) | Notched impact strength (J/m) | Appearance | Carbon footprint t CO2e/t | Certification | Typical Application |

|---|---|---|---|---|---|---|---|---|

| rPETG-T304A | 3~8 | 100% | ≥40 | ≥70 | Transparent | 0.9432 | GRS/JSCC PLUS | Merge/Blow Molding |

| rPETG-T104A | 7~12 | 100% | ≥40 | ≥70 | Transparent | 0.9443 | GRS/JSCC PLUS | Injection molding |

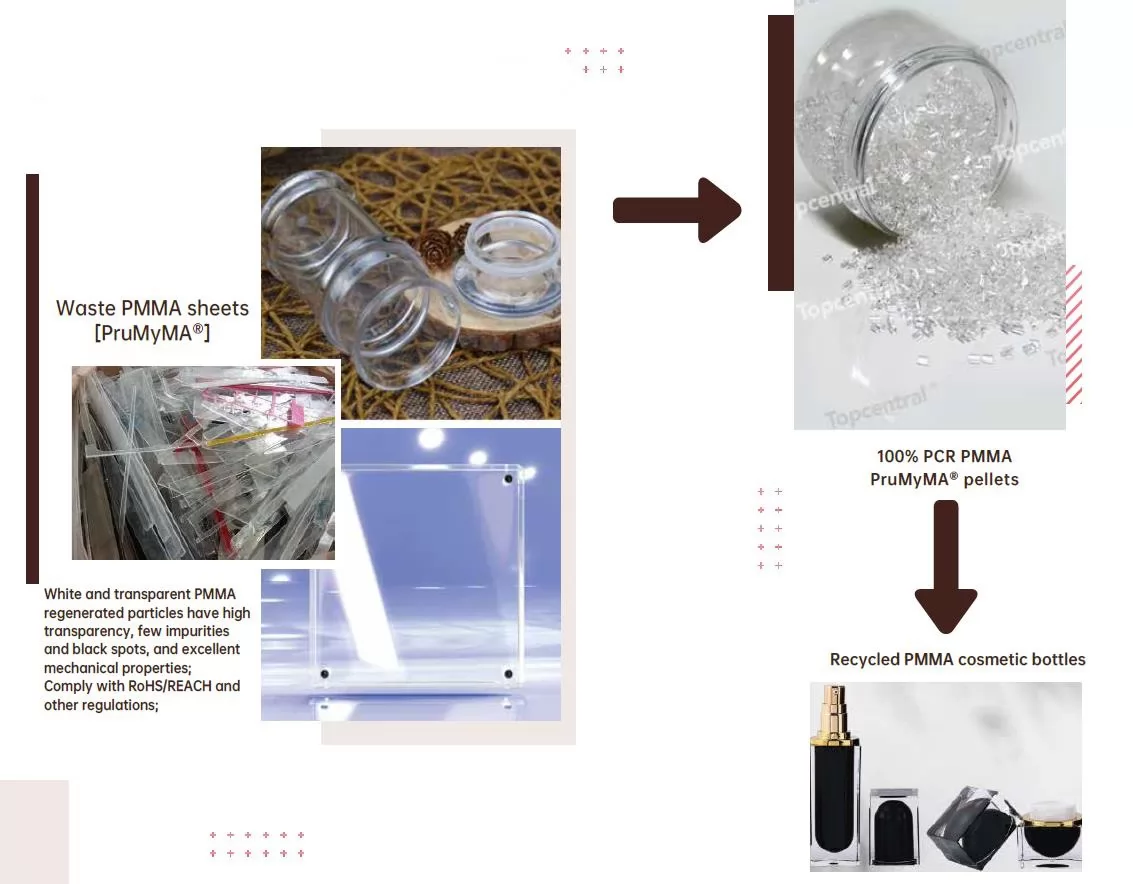

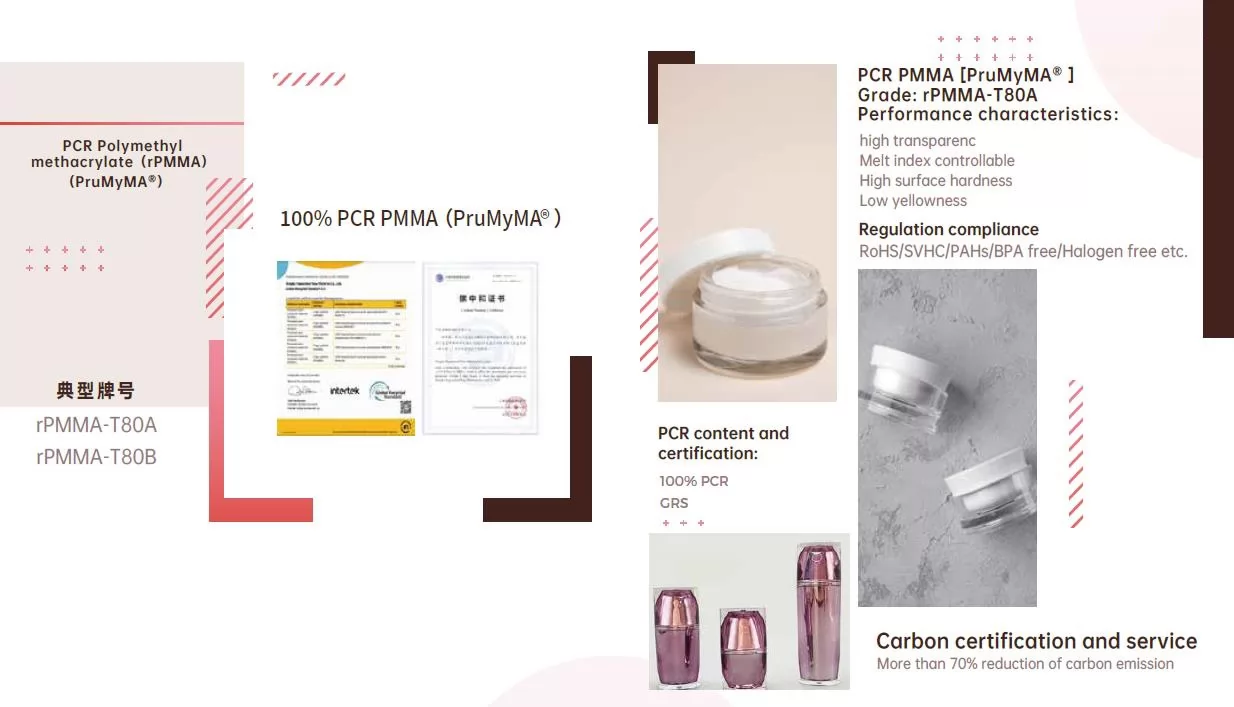

| Typical grade | Melt index (g/10min) | Notched impact strength (KJ/m²) | PCR content (%) | Appearance | Carbon footprint CO₂e/t | Certification | Application |

|---|---|---|---|---|---|---|---|

| rPMMA-T80A | 1~10 | 88 | 100% | Transparent | 0.6051 | GRS | Extrusion/injection molding/extrusion blow |

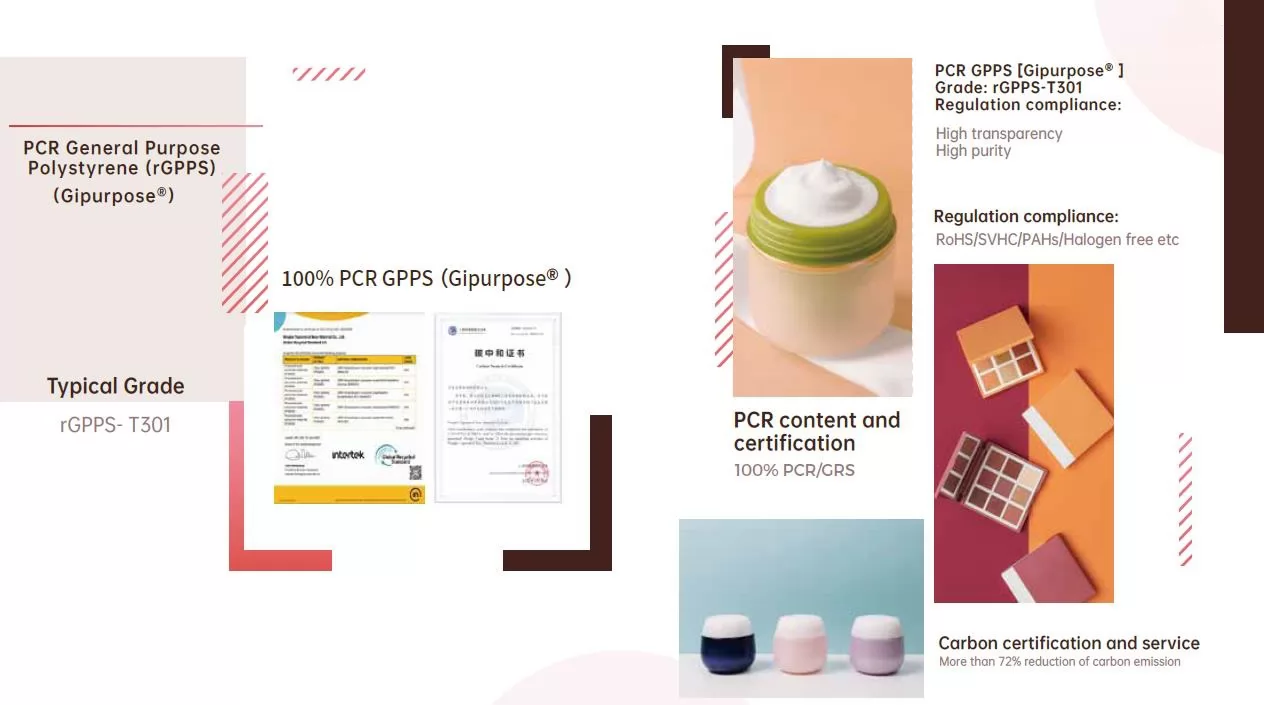

| Typical grade | Melt index (g/10min) | PCR content | Tensile strength (MPa) | Notched impact strength (J/M) | Bending strength (MPa) | Appearance | Carbon footprint t CO2e/t | Certification | Typical Application |

|---|---|---|---|---|---|---|---|---|---|

| rGPPS-T301 | 3~10 | 100% | ≥32 | ≥25 | ≥85 | Transparent | 0.6428 | GRS/SCC PLUS | Injection molding/modification |

| Typical grade | Melt index (g/10min) | PCR content (%) | Transmittance (%) | Carbon footprint t CO2e/t | Appearance | Certification | Typical Application |

|---|---|---|---|---|---|---|---|

| rAS-T140 | 30-50 | 100% | ≥80 | 0.6507 | Transparent | GRS/ISCC PLUS | Injection molding |