Answer Revealed: PPS, the "All-Round Warrior" of the Materials World

Parpus™ rPPS by Topcentral®

Imagine a material that thrives beside scorching boilers, stands unshaken in the face of strong acids and alkalis, and shows no fear when exposed to flames—this is Polyphenylene Sulfide (PPS). This all-round warrior in the materials world is quietly transforming our lives with its unique performance traits.

Exceptional Heat Resistance: PPS can continuously operate at 190℃ and withstand peak temperatures up to 220℃. Even after prolonged exposure to high heat and humidity, its strength remains virtually unaffected. This thermal stability makes it an ideal choice for high-temperature filtration and automotive engine components.

Outstanding Corrosion Resistance: PPS resists almost all acids, alkalis, and organic solvents, with the exception of strong oxidizers. Its "poison-proof" capability allows it to shine in chemical pipelines and environmental equipment.

Inherent Flame Retardance: PPS meets the UL94 V-0 flame retardant standard without any additional flame retardants. Once the flame is removed, it self-extinguishes. This innate fire resistance makes it a reliable safety material in electronics and aerospace sectors.

Electronics and Electrical: PPS is a mainstay in connectors, coil bobbins, and relays. Its heat and flame resistance ensure precision components perform reliably under extreme conditions.

Automotive: In automotive manufacturing, PPS plays a critical role in lightweighting. From intake manifolds to turbo components and electronic water pump housings, PPS handles both corrosive fluids and high temperatures while reducing vehicle weight.

Aerospace: PPS also excels in aerospace. Aircraft like the Airbus A350 and Gulfstream G650 use carbon fiber-reinforced PPS composites in fuselage connectors and control surfaces. These materials are lightweight, strong, and stable under extreme temperatures.

To make PPS even more versatile, scientists have developed various modification techniques:

Glass Fiber Reinforcement: Adding 20%-40% glass fiber significantly enhances PPS's strength and heat resistance, making it popular for EV battery enclosures and electrical housings.

Carbon Fiber Composites: The combination of PPS and carbon fiber yields lightweight and impact-resistant components such as automotive wheels and structural parts.

Blended Modifications: Mixing PPS with materials like PPE and PTFE further broadens its capabilities. PPS/PPE blends are suitable for engine cylinder heads, offering heat resistance and dimensional stability. PPS/PTFE composites feature self-lubricating properties, perfect for wear-resistant parts.

Anti-Static Modification: Adding graphite and conductive materials turns PPS into an anti-static specialist, widely used in optoelectronic and electromagnetic equipment.

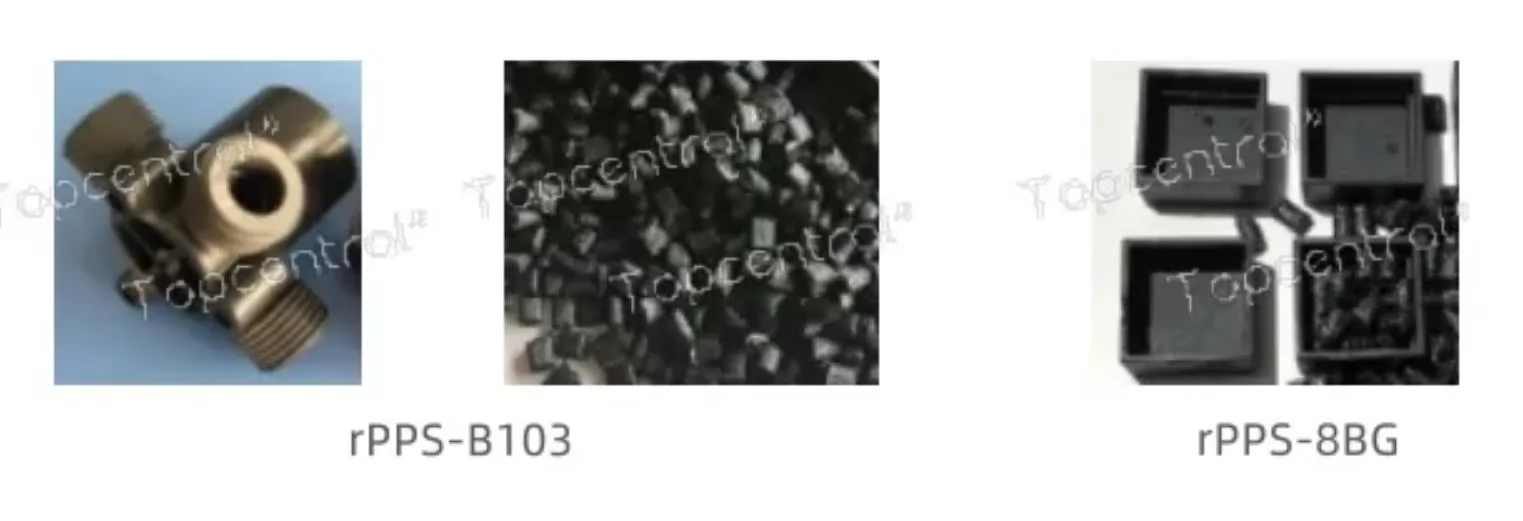

PPS has a productive "retirement" too. Through crushing and remelting, waste PPS is reprocessed into powder or pellets for use in new plastic parts or as a flame retardant additive. Recycled PPS finds new life in environmental equipment and automotive components.

Next time you see high-temperature equipment running steadily or an electric vehicle gliding effortlessly, think about PPS powering those feats behind the scenes.

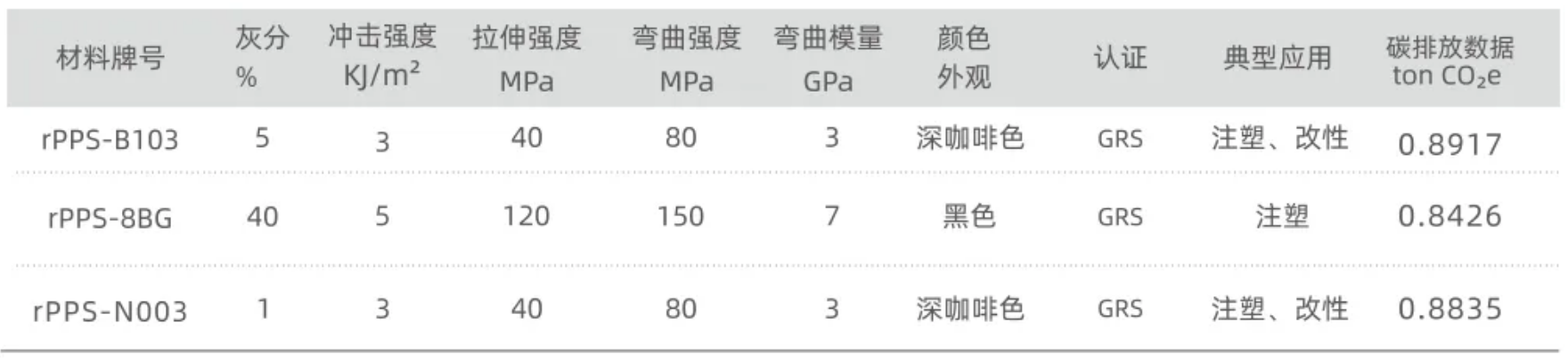

PCR Polyphenylene Sulfide (PCR rPPS) is made from post-consumer products (including but not limited to dust filter bags and electronic mechanical parts), and processed through pretreatment, granulation, and modification. Depending on the source and grade of recycled material, Topcentral® offers classified selection, technical innovation, performance optimization, and high-quality automated production to deliver injection-grade PCR PPS tailored to various industry needs. Customized system-level solutions are also available.

Taosu®

Topcircle®

TcycleEp®

Parpus™

Precision control over raw material sources and quality, with strict process and quality management, ensuring stable and sustainable performance with full traceability across the value chain.

Compliant with RoHS and GRS standards.

Fully customizable solutions available based on client requirements.

Carbon footprint and emission calculation data and certifications available.

Suitable for modification, injection molding, and high-grade products for producing various injection-molded parts.

Discover this amazing content and share it with your network!

Discover the successful Ningbo session of the 9th National Coastal Cleanup Campaign. Families, youth, and eco-teams united to protect the ocean, advocate recycling, and promote sustainable coastal action.

Explore recycled AS pellets: transparent, BPA-free, high-performance sustainable plastic for consumer goods, packaging, electronics, and automotive applications.

Topcentral® joined China’s national delegation at K 2025 Düsseldorf to promote sustainable polymer innovation and global circular economy collaboration.