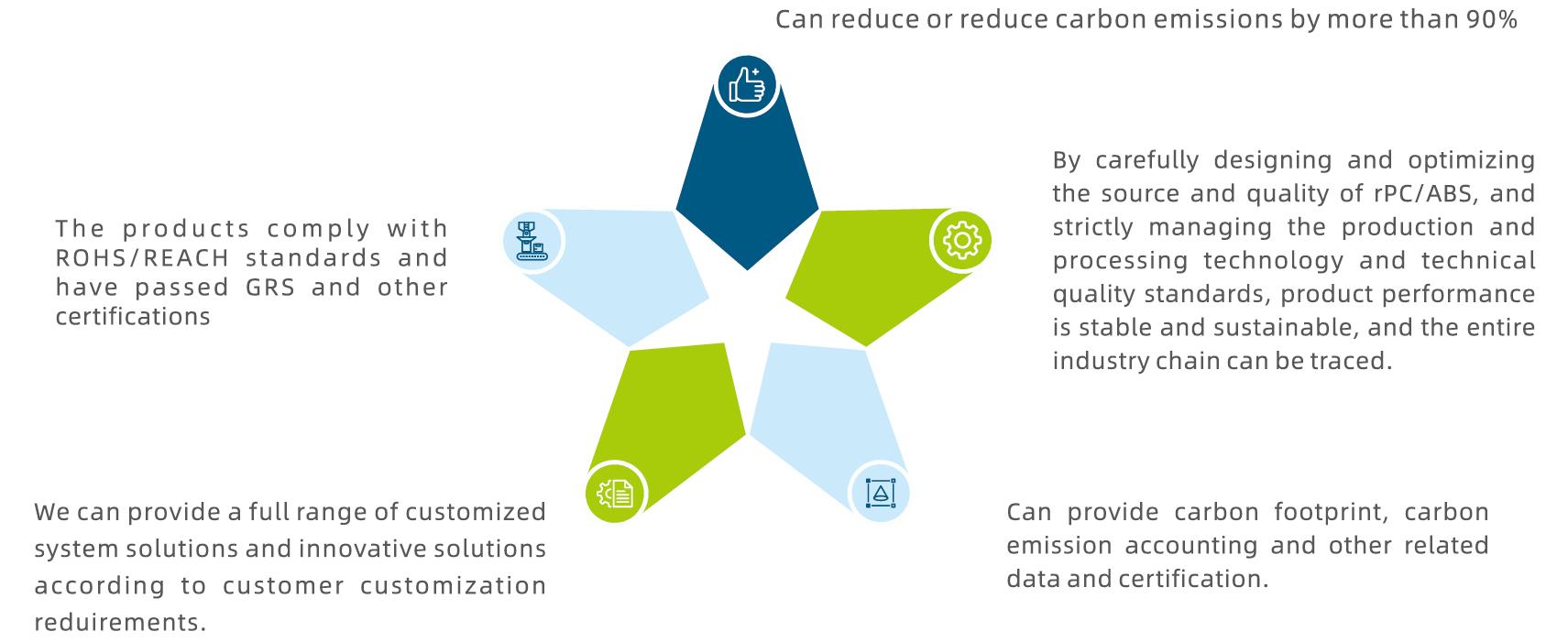

PCR alloy materials are plastic particles prepared through preprocessing and standardized granulation processes, sourced from post-consumer recycled products, including but not limited to automobiles, household appliances, communication equipment, and consumer electronics. Based on different recycling sources and quality grades, we employ design classification, technological innovation breakthroughs, performance optimization, and high-quality automated production processes. We offer customers extrusion-grade and injection molding-grade PCR alloy particles. The colors available include, but are not limited to, natural, black, white, etc., catering to diverse application needs in the industry. Moreover, we can provide comprehensive customized system solutions based on specific requirements from customers.

| Material grade | MFI (g/10min) | IZoDI impact strength (KJ/m²) | Exterior color | Typical application | Product features | Carbon emissions ton CO2e |

|---|---|---|---|---|---|---|

| rPC/ABS-N145 | 10-30 | ≥30 | Nature Color | Injection molding modification | Excellent processing performance | 0.8212 |

| rPC/ABS-B115 | 10-20 | ≥12 | Black | Injection molding modification | Excellent processing performance | 0.7946 |

Topcircle® TCycleAlloy™;

We offer a wide variety of materials, including general plastics, engineering plastics, and specialty plastics, covering almost all types of recycled polymers.

With a dedicated R&D team, we continuously innovate and develop high-performance, customized material solutions to meet diverse industry needs.

From research and testing to manufacturing and sales, we provide end-to-end solutions, streamlining the supply chain for our clients.

Our products promote low-carbon, circular economy practices,supporting global sustainability efforts with bio-based and degradable materials.

Sustainable low - carbon functional materials are applied across numerous critical areas. In the energy sector, they are pivotal. For instance, advanced photovoltaic materials with low - carbon manufacturing processes are used to construct more efficient solar panels. These materials enhance the conversion of sunlight into electricity, contributing to the expansion of renewable energy sources and reducing reliance on fossil fuels.

In the textile industry, sustainable low - carbon functional materials are making waves. Bio - based and recycled fibers are being used to create fabrics. These materials not only consume less energy during production but also have a lower environmental impact compared to traditional synthetic fibers. Moreover, some functional textiles made from these materials can regulate body temperature, repel water, or provide UV protection, all while maintaining a low - carbon footprint.

In the textile industry, sustainable low - carbon functional materials are making waves. Bio - based and recycled fibers are being used to create fabrics. These materials not only consume less energy during production but also have a lower environmental impact compared to traditional synthetic fibers. Moreover, some functional textiles made from these materials can regulate body temperature, repel water, or provide UV protection, all while maintaining a low - carbon footprint.