Sustainable High-Performance Recycled Polyethylene Solutions for Industrial Applications

PCR PE (Post-Consumer Recycled Polyethylene) represents our commitment to sustainable plastic solutions, transforming end-of-life products into high-quality recycled materials. Our Poisye® rPE product line delivers exceptional performance while supporting circular economy principles and reducing environmental impact.

Poisye® rPE is produced through advanced recycling processes including post-consumer product collection, pretreatment, standardized granulation, and other technological processes. Based on different recycling sources and quality grades, we implement special classification methods, technological innovation, and high-quality automatic processing to produce superior products.

Our PCR PE product range includes blow molding grade, extrusion grade, and injection molding grade rPE pellets. Available colors include natural color, black, white, and green, which can meet the diverse application needs of customers across various industries. We also provide all-round customized system solutions and innovative solutions according to the special requirements of customers.

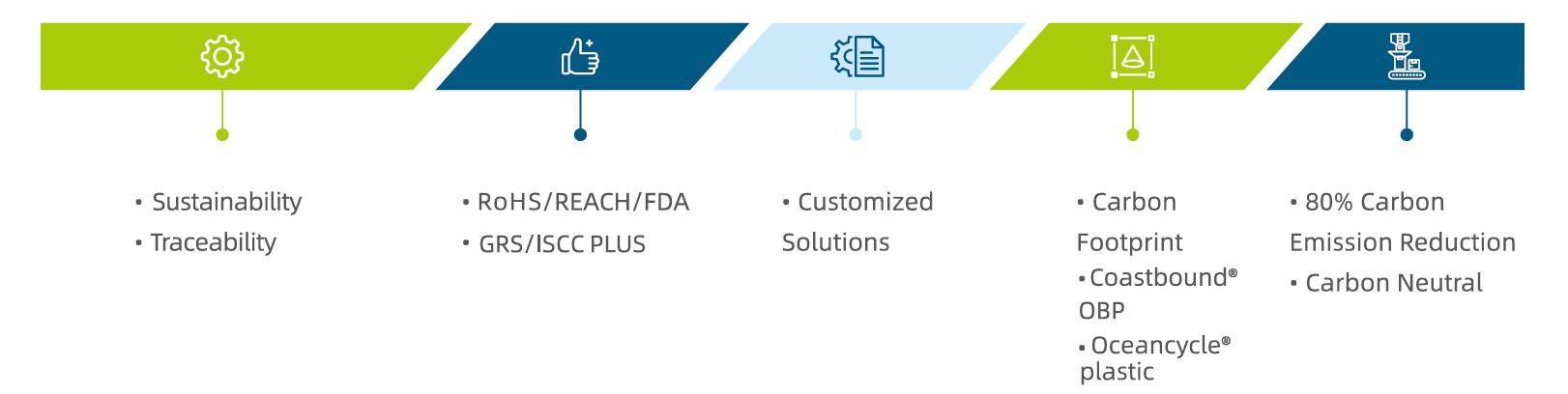

Transforming post-consumer waste into high-quality PCR PE materials supporting circular economy principles and sustainable manufacturing.

GRS, ISCC PLUS, SCS Global, and UL OBP certified PCR PE materials ensuring traceability, sustainability, and consistent performance.

Available in HDPE and LDPE grades for blow molding, extrusion, and injection molding with various MFR values to meet specific needs.

Available in natural color, black, white, and green variants to meet diverse application requirements and aesthetic needs.

International certifications ensuring sustainable and safe PCR PE materials

Our PCR PE materials meet international standards for recycled content verification, environmental management, and product safety. These certifications provide assurance of sustainable sourcing, reduced carbon footprint, and consistent quality for your applications.

Comprehensive PCR PE grades for diverse industrial applications

Our PCR PE product line offers excellent mechanical properties including high tensile strength, good impact resistance, and versatile flow characteristics suitable for various processing methods. All grades are available with GRS/ISCC PLUS certifications ensuring traceability and sustainable sourcing. Carbon emissions range from 0.6087 to 0.6312 ton CO₂e per ton of product, significantly lower than virgin polyethylene production.

| Typical Grade |

MFR g/10min |

Tensile Strength MPa |

IZOD Notched Impact Strength KJ/m² |

Appearance | Certification | Application |

Carbon Emissions ton CO₂e |

|---|---|---|---|---|---|---|---|

| rHDPE-W105A | 0.1~1 | ≥20 | ≥20 | Natural Color | GRS/ISCC PLUS | Blow Molding, Extrusion | 0.6216 |

| rHDPE-W180A | 5~10 | ≥18 | ≥4 | Natural Color | GRS/ISCC PLUS | Injection | 0.6129 |

| rHDPE-Ocean78A | 0.1~8 | ≥16 | ≥3 | White, Black | SCS Global/GRS | Blow Molding, Extrusion | 0.6087 |

| rLDPE-W210A | 0.2~5 | ≥10 | / | Natural Color | GRS/ISCC PLUS | Blow Molding, Extrusion | 0.6179 |

| rPE-BP06 | 0.1~6 | ≥16 | ≥3 | White, Black | GRS/UL OBP/ISCC PLUS | Blow Molding, Extrusion | 0.6125 |

| rHDPE-B110P | 0.5~2 | ≥18 | ≥15 | Black | GRS/UL OBP/ISCC PLUS | Extrusion | 0.6312 |

| rHDPE-G110P | 0.5~2 | ≥18 | ≥15 | Green | GRS/UL OBP/ISCC PLUS | Extrusion | 0.6279 |

Comprehensive recycled material brands for circular economy solutions

Core PCR PE product line with full certification coverage for HDPE and LDPE applications.

Zero-carbon certified recycled polyethylene solutions for carbon neutrality goals.

Ocean plastic sourced recycled materials helping protect marine environments.

Ocean-bound plastic collection programs preventing plastic pollution at source.

Versatile recycled polyethylene for diverse industrial applications

Hollow containers, bottles, and drums requiring excellent chemical resistance and durability for packaging applications.

Pipes, tubes, and profiles for construction, plumbing, and industrial applications requiring high strength.

Various molded parts, crates, pallets, and industrial components requiring impact resistance and dimensional stability.

Plastic films for packaging, agricultural applications, and industrial use requiring consistent quality and processability.

Rigid and flexible packaging solutions for food, chemicals, and consumer products.

Construction materials, automotive parts, and industrial containers requiring durability and cost efficiency.

Products can be used in hollow containers, extruded pipes, injection molded products, films and some other fields according to different MFR. Our PCR PE materials offer excellent processability and consistent quality for demanding industrial applications.

Technical recommendations for optimal PCR PE processing performance

Drying Temperature: 60-80°C

Drying Time: 1-2 Hours

Moisture: <0.2%

Melt Temp: 180-240°C

Mold Temp: 20-40°C

Injection Pressure: 40-80 MPa

Melt Temp: 170-210°C

Parison Temp: 160-190°C

Blow Pressure: 0.3-0.5 MPa

Melt Temp: 180-220°C

Screw Speed: 30-120 rpm

Cooling: Water bath or air

Note: These are general guidelines. Specific processing parameters may vary depending on equipment, part design, and specific grade requirements. Please consult our technical team for detailed recommendations.

Measurable environmental benefits of choosing PCR PE

Your trusted partner for sustainable polyethylene solutions

We offer a wide variety of PCR PE grades including HDPE and LDPE for blow molding, extrusion, and injection molding applications.

With a dedicated technical team, we continuously innovate and develop high-performance, customized PCR PE solutions for specific industry needs.

From raw material sourcing to processing and delivery, we provide end-to-end solutions ensuring consistent quality and supply stability.

Our PCR PE products promote circular economy practices, helping customers achieve sustainability targets and reduce environmental impact.

Discover how our recycled polyethylene can help you achieve your sustainability goals while maintaining excellent product performance and cost efficiency.

Request a Quote Get Free Sample

We offer a wide variety of materials, including general plastics, engineering plastics, and specialty plastics, covering almost all types of recycled polymers.

With a dedicated R&D team, we continuously innovate and develop high-performance, customized material solutions to meet diverse industry needs.

From research and testing to manufacturing and sales, we provide end-to-end solutions, streamlining the supply chain for our clients.

Our products promote low-carbon, circular economy practices,supporting global sustainability efforts with bio-based and degradable materials.

Sustainable low - carbon functional materials are applied across numerous critical areas. In the energy sector, they are pivotal. For instance, advanced photovoltaic materials with low - carbon manufacturing processes are used to construct more efficient solar panels. These materials enhance the conversion of sunlight into electricity, contributing to the expansion of renewable energy sources and reducing reliance on fossil fuels.

In the textile industry, sustainable low - carbon functional materials are making waves. Bio - based and recycled fibers are being used to create fabrics. These materials not only consume less energy during production but also have a lower environmental impact compared to traditional synthetic fibers. Moreover, some functional textiles made from these materials can regulate body temperature, repel water, or provide UV protection, all while maintaining a low - carbon footprint.

In the textile industry, sustainable low - carbon functional materials are making waves. Bio - based and recycled fibers are being used to create fabrics. These materials not only consume less energy during production but also have a lower environmental impact compared to traditional synthetic fibers. Moreover, some functional textiles made from these materials can regulate body temperature, repel water, or provide UV protection, all while maintaining a low - carbon footprint.