At CHINAPLAS 2025, Topcentral® (Ningbo Topcentral New Material Co., Ltd.) welcomed a special guest— a reporter from the Japan Chemical Industry Daily, Japan’s most prominent chemical industry media outlet. The journalist conducted an in-depth interview with Topcentral®’s founder and CEO, Mr. Ma Yiming, gaining insight into the company’s innovations in circular economy and marine plastic pollution governance. This exclusive report was recently published by the authoritative Japanese media, drawing attention not only in China’s chemical industry but also sparking significant interest within Japan’s chemical sector in China's innovative marine pollution solutions.

As a founding organizer of the "China-Japan Petrochemical Industry Conference", Japan Chemical Industry Daily is the largest specialized media outlet in Japan’s chemical industry, covering a broad range including life sciences and information electronics.

The media outlet has long-standing ties with the China Petroleum and Chemical Industry Federation. In November 2024, a CPCIF delegation visited the publication’s leadership, where both parties reached consensus on topics such as carbon footprint accounting and international treaty negotiations.

The report on Topcentral® recognizes its technological and business model innovations in plastic recycling and marine plastic governance, acknowledging them as internationally validated achievements. It highlights how Topcentral® converts marine plastic pollution into valuable resources through technological advancements—offering a “China Solution” for global ocean protection.

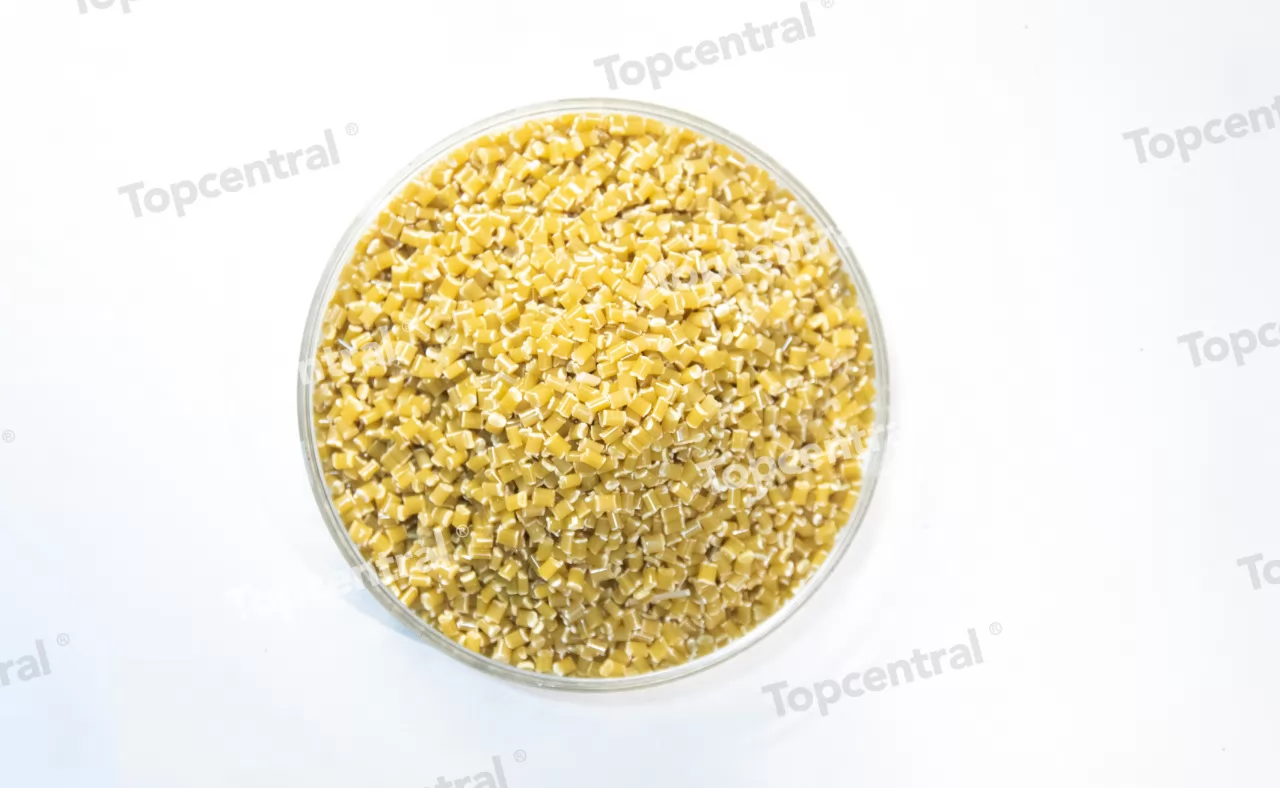

At the 2025 Ringier Technology Innovation Awards, Topcentral®’s marine recycled material rABS-Ocean78A made waves. Using physical recycling, it achieves stable MFI (18g/10min ±5%) and a high HDT of 98°C—rivaling virgin materials.

Its core value lies in its carbon reduction impact: every ton reuses 1.2 tons of marine waste, reducing lifecycle carbon emissions by 78%—equivalent to 3.5 tons less CO₂. Judges praised the tech for “transforming environmental burden into resource value.”

Topcentral®’s product portfolio spans four major lines—Topcircle®, Circleblend®, Bydercom®, and CHEMCIRCLE®—covering nearly all plastic categories. These high-performance recycled materials are used in electronics, automotive, home appliances, and communication industries.

The company owns 70 patents (over 50% are invention patents), has led 3 national standards and 2 group standards, and manages 287 trademarks—demonstrating strategic control over its intellectual property landscape.

Topcentral®’s R&D pipeline ensures full-chain coverage, from molecular design and recycling process development to application innovation, enabling seamless industrialization and swift market responsiveness.

More than its technological breakthroughs, Japanese media spotlighted the “Ocean Partner” ecosystem developed by Topcentral®. It tackles three global marine plastic challenges:

Collection difficulty: 11 coastal sites in Ningbo and Zhoushan with “eco pods + ocean trace kiosks + recycling stations”.

High-value reuse: Production of electric toothbrushes, caps, T-shirts, etc.

Multi-stakeholder governance: Carbon credit incentives for fishermen, tourists, and more.

In Qifeng Fishing Village, a converted container now serves as an “eco pod”. Fishermen earn carbon credits by recycling marine waste, redeemable for cultural products or coffee. In under two years, over 1,400 tons of marine plastic has been processed, building an innovative system integrating recycling, public education, tourism, and green business.

The project aims to fully transform ocean waste into valuable resources, used in packaging, textiles, industrial manufacturing, and cultural products—often with over 50% value premium. Carbon footprint labeling certified by global authorities links marine recycling with environmental governance and inclusive growth.

Topcentral® is redefining the plastic industry chain. Leveraging blockchain, cloud computing, and big data, it enables real-time carbon footprint tracking and establishes a full-lifecycle traceability system for recycled plastics.

Its integrated digital platform—Back2Circle® traceability chain + TraceBytes blockchain + PCFNOW real-time carbon footprint engine—applies “carbon labels” across sourcing, manufacturing, logistics, usage, and recycling. Products are assigned traceable codes, aiding ESG evaluations and promoting sustainable development across supply chains.

In an interview with Japanese media, CEO Ma Yiming outlined Topcentral®’s globalization roadmap: starting with a smart model factory in Ningbo—complete with green sorting and manufacturing centers powered by wind, solar, and hydro energy—targeting zero emissions.

This vision aligns with Sino-Japanese industry cooperation goals. The CPCIF and Japan Chemical Industry Daily jointly emphasize platforms for tech exchange and co-development.

As marine plastic pollution draws increasing global attention, Topcentral®’s solutions offer scalable models for marine governance. Its concept of a “Circular Plastic Metaverse” envisions a new future where plastics enter an “infinite recycling universe.”

The in-depth coverage by Japanese media brings the “Ocean Partner” model to the global stage. From volunteers picking up plastic bottles on Qifeng Beach, to fishermen trading waste for coffee in Fenghua, to international clients holding eco-pens at trade shows—China’s solutions are connecting the dots of ocean preservation worldwide. As the smart factory rises, these coastal innovations may hold the key to reversing the “more plastics than fish by 2050” crisis.

Ningbo Day at the 2025 Osaka World Expo showcased the city's cultural charm, technological innovation, and environmental solutions, highlighted by Jianfeng's "Ocean Partner" project, promoting global cooperation.

Discover the top 10 recycled plastic manufacturers in 2025, including global leaders like Veolia and SUEZ, plus recommended manufacturer Topcentral. Explore their innovations in rPET, rPE, and sustainable solutions.

Discover the unmatched durability, oil resistance, and eco-performance of Pubit® rPBT keycaps. Designed for long-term use and crafted from recycled PBT, these keycaps outperform ABS in every way—from gaming to coding to sustainability.